Plywood Cutting & Machining

We offer a comprehensive cutting and machining service

Cut sizes from UK stocked panels or direct from the plywood mill for larger volumes

As importers, we process commercial volumes only

Cutting & Machining Service

Sheet materials cut to any size with a tolerance of +/- 0.5mm

Machines

Beam Saw - for standard panel cutting

CNC 3 axis - used for the majority of our machining, edge profiles, complex cutting

CNC 5 axis - produces 3D machined components

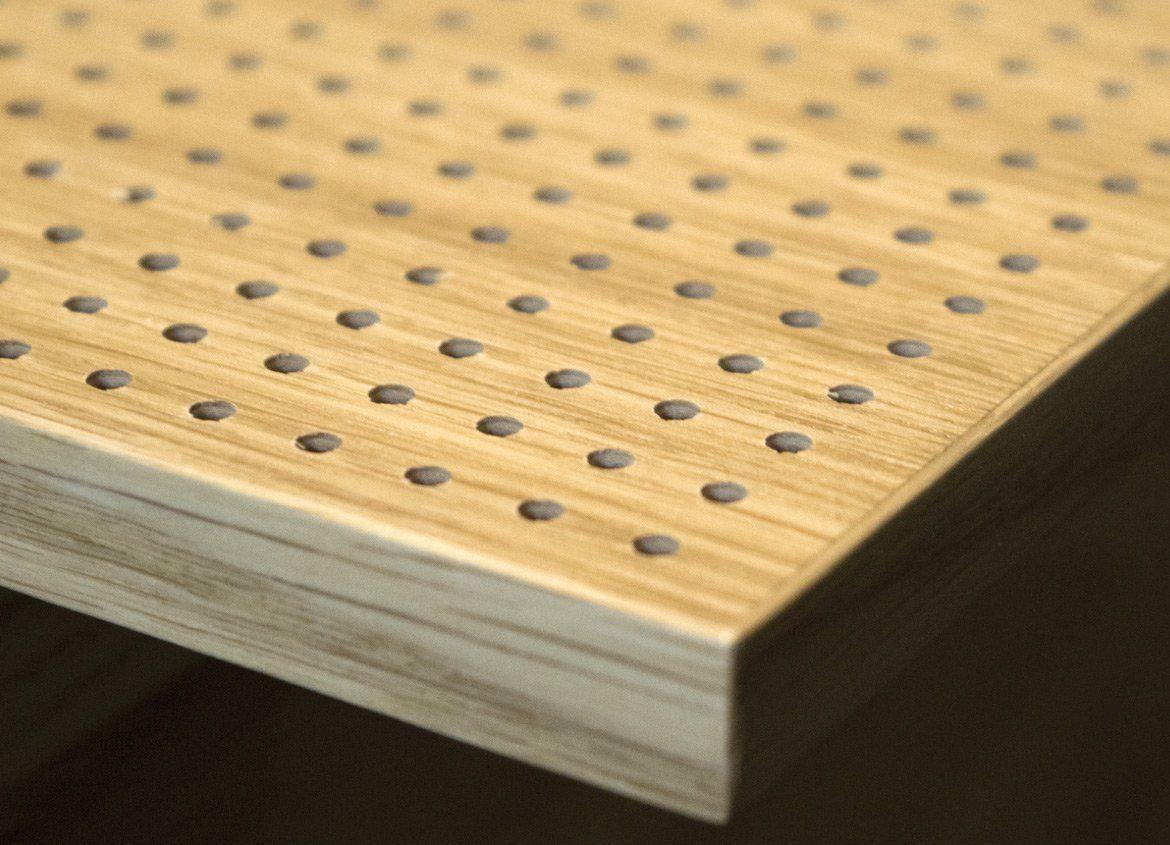

Multihead CNC - used for acoustic perforation, peg boards

Square-Edge Cutting

For basic square and rectangle panels. Cut on a beam saw capable of handling large panels

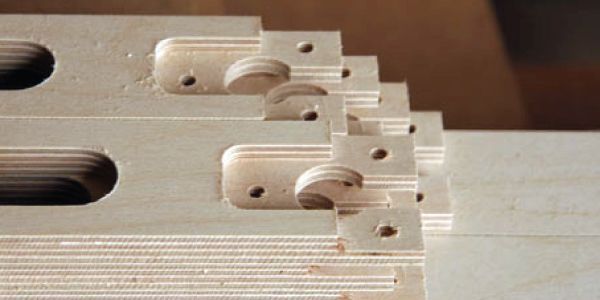

CNC Machined

For more complex components that include routering and drilling

Machined Edges

Chamfered - usually at a 45 degree angle by 5mm or more. Designed to ease/soften the panel edge.

Micro Chamfer - a subtle chamfer 5mm or less.

Bevel - running along one edge. Choice of angle and depth.

T&G (Tongue & Groove) - T&G2LE (two long edges) or T&G2SE (two short edges). Often machined on panels for flooring applications.

Loose Tongue & Groove - grooved edges with a separate strip (usually plywood) inserted between panels. Can be painted for contrast.

Bullnosed - rounded on top and bottom edge, often used in furniture.

Fixings Joints - dove-tail, finger joint, mitre joints, lap joints, drilled holes for dowels

Edge Sealed

Phenol faced panels are edged sealed with an exterior paint to prevent water ingress

Edge Banding

ABS edging for protection or veneer edge band for decorative finish

Leadtimes

We hold stock of popular material, ready for cutting within 7-10 working days

This includes phenol faced birch plywood in 9mm and 18mm and plain birch in 12mm, 15mm and 18mm

For mill production on a forward order basis, allow 7-8 weeks

Software Files

We can accept drawing files in the following formats:

PDF - DXF - DWG - DWF - CAD - STEP - RVT

We deliver throughout the UK

Request a Quote

Plywood Cutting & Machining

We offer a comprehensive

cutting and machining service

Cut sizes from UK stocked panels or direct

from the plywood mill for larger volumes

As importers, we process

commercial volumes only

Cutting

& Machining

Service

Sheet materials cut to any size

with a tolerance of +/- 0.5mm

Machines

Beam Saw

For standard panel cutting

CNC 3 axis

Used for the majority of our machining

edge profiles & complex cutting

CNC 5 axis

Produces 3D machined components

Multihead CNC

Used for acoustic perforation, peg boards

Square-Edge Cutting

For basic square and rectangle panels

Cut on a beam saw capable

of handling large panels

CNC Machined

For more complex components

that include routering and drilling

Machined Edges

Chamfered

Usually at a 45 degree angle by 5mm or more

Designed to ease/soften the panel edge

Micro Chamfer

A subtle chamfer 5mm or less

Bevel

Running along one edge

Choice of angle and depth.

T&G (Tongue & Groove)

T&G2LE (two long edges)

T&G2SE (two short edges)

Often machined on panels

for flooring applications

Loose Tongue & Groove

Grooved edges with a separate strip

(usually plywood) inserted between panels

Can be painted for contrast

Bullnosed

Rounded on top and bottom edge

often used in furniture

Fixings Joints

Dove-tail, finger joint, mitre joints

lap joints, drilled holes for dowels

Edge Sealed

Phenol faced panels are edged sealed with an exterior paint to prevent water ingress

Edge Banding

ABS edging for protection or veneer edge band for decorative finish

Leadtimes

We hold stock of popular material, ready for cutting within 7-10 working days

This includes

phenol faced birch plywood in 9mm and 18mm

plain birch in 12mm, 15mm and 18mm

For mill production on a forward order basis

allow 7-8 weeks

Software Files

We can accept drawing files

in the following formats:

PDF - DXF - DWG

DWF - CAD - STEP - RVT

We deliver throughout the UK

Request a Quote