Fire Retardant Timber

Increases Evacuation Time

Reduces the Rate of Fire Spread

Reduces Smoke

We hold test certification on the following species:

What Species Can Be Treated?

| Solid Wood Species | Density | Min. Thickness | Reaction To Fire Classes |

|---|---|---|---|

| Spruce | 350-600 | 15 mm | B-s1;d0 |

| Pine | 450-600 | 20 mm | B-s1;d0 |

| Oak | 500-750 | 20 mm | B-s1;d0 |

| Cedar | 350-450 | 20 mm | B-s2;d0 |

| Siberian Larch | 650-750 | 21.5 mm | B-s1;d0 |

| Modified Wood Species | Density | Min. Thickness | Reaction To Fire Classes |

|---|---|---|---|

| Thermo Ash | 590-650 | 21.5 mm | B-s1;d0 |

| Thermo Pine | 450-500 | 19mm | B-s1;d0 |

| Thermo Ayous | 550-550 | 19mm | B-s1;d0 |

| Thermo Obeche | 550-550 | 19mm | B-s1;d0 |

| Accoya | 400-700 | 19 mm | B-s1;d0 |

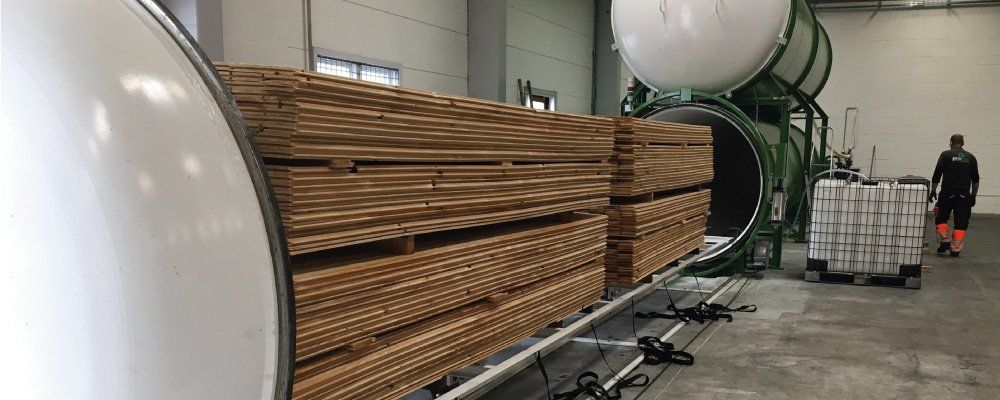

Pressure impregnated with a fire-retardant solution to meet the requirements of Euro Class B or Euro Class C for fire retardant classification projects. Contra-Burn fire-retardant is designed to reduce surface spread of flame, smoke and heat generation, whilst maintaining the natural durability and strength of the wood.

Contra-Burn is a non-toxic water based treatment containing only food grade ingredients, ensuring no hazardous chemical risks to treaters and users of the product. Oxygen supply is effectively blocked in the fire-threatened material. In this way Contra-Burn halts the burning process, just as it can counteract the ignition of treated plywood and timber.

Contra-Burn treatment is completed under ISO9001 controlled factory conditions and is approved to the highest classification according to the Euroclass system for building products, making it the perfect solution for most building projects. Full test data available on request.

What is Contra-Burn® Treated Timber?

Non-Toxic

- No ingredient of

Contra-Burn

is on the REACH list or REACH candidate list

- 100% Organic. In its liquid form, bio-degrades in 14 days

- Non-harmful and non-hazardous. 100% food grade ingredients

- Waste Management - safe disposal, treat as normal plywood

- Handling - no additional masks or gloves

- No additional cost implications for storage, handling & disposal

Borate Free

- Traditionally, borates are used in fire rated timber and plywood

- Sodium perborate is on the REACH candidate list of substances for very high concern

- Sodium perborate meets the criteria to be classified as toxic for reproduction. Read the ECHA support document

here

- Contra-Burn is borate free

Why Choose Contra-Burn®?

Service Life of Contra-Burn Treated Wood

Contra-Burn

treatment is designed to last the life of the wood and has undergone testing to ensure durability in application. Therefore,

Contra-Burn

treated wood requires no additional maintenance to maintain the given Euro Class.

Documentation

Contra-Burn

fire-retardant is fully supported by independent tests, including species specific laboratory classification reports, which fully document the effects of treatment on natural wood products.

All technical documentation is available upon request from one of our technical team.

Natural wood products can exhibit minor changes to appearance once treatment has been completed.

Vacuum impregnation process involves incorporating fire-retardant chemical into the natural wood, followed by kiln drying. Existing minor imperfections within the wood, can become more noticeable.

Dependent upon the wood species, colour variations are possible too, with slight darkening and highlighting of grain. This will fade to match non-treated timber over time, with weathering. Chemical residue may remain on the wood following treatment. Due to the non-toxic composition of Contra-Burn, this can be wiped off, leaving no long-lasting effect to the final product appearance.

Please discuss your project with us, we can ensure you are fully aware of potential changes to Contra-Burn treated wood.

What is the Appearance of Treated Timber?

Contra-Burn® Applications

Contra-Burn fire-retardant wood-based products can be used in above ground internal and external applications, dependent upon the durability of the product used. This includes key visual items such as fire retardant cladding and decking, fire retardant moulding and general construction such as fire retardant joists and fire retardant battens. The product can be allowed to naturally weather in application, or it can be coated with an approved coating system.

We advise speaking to one of our technical team to discuss product application.

Additional Services

- Bespoke profile cutting

- Cut to length sections

- CNC work

- Factory applied coatings

What is Fire Retardant (FR) Plywood and Timber?

FR timber and plywood is material that has been treated to slow the spread of fire propagation and prevent ignition. The spread of flame is measured against a known standard of EN 13501-1.

Why is FR material specified?

Increases the available time to safely evacuate a burning building

Reduces the rate of fire spread

Reduces smoke

By using FR Timber or FR Plywood you are using material that has passed and been approved to a measured standard as outlined in the Building Regulations. Treated material behaves and reacts to fire in a known and quantifiable way.

Class B or Class 0?

Class 1 and 0 were British standards BS476-7 which had started to be phased out in 2008 and completed by 2013. The standards were replaced by a harmonised European Standard. Document B refers to this harmonisation.

Document B

Building Regulations and Fire Safety Standard (2010 and 2013 amendments) - Fire Safety: Approved Document B

Volume 1 - Dwelling Houses. Volume 2 - Buildings other than Dwelling Houses.

This is a government document that specifies building regulations concerning fire. Public and private buildings 3m or 4m high.

This document outlines how to build a structure to achieve building “sign-off” from the building inspector. A Fire Officer is also involved.

The Architect and Structural Engineer will refer to Document B:

External Link to Document B

Resistance / Reaction to Fire

Resistance is measured in time (e.g. a 30 minute fire door) and usually relates to a composite, an assembled product or a constructed setup.

Reaction usually relates to individual material components, such as timber and plywood, where they are sold with a known and measured reaction to fire.

These are two different tests.