European Oak Cladding

Construction companies - Civil engineering

Large scale housing or building projects - Architects

Construction Companies

Civil Engineering

Large-scale Housing or Building Projects

Architects

A highly durable, moderately stable timber which offers a relatively clean look with attractive figuring. Oak is a traditional cladding material, due primarily to an excellent level of durability, particularly when compared to other temperate hardwoods. European Oak has a distinctive grain with annual growth rings visible on crown cut boards. Quarter cut boards will have distinct silver grain figure due to the broad rays. Generally straight grained, hard wearing and durable, Oak offers a very attractive cladding solution. There are relatively few knots in the wood and it has attractive figuring, therefore this species may be considered if you are looking for a clean and contemporary look.

Specifications

Appearance: Yellowish to golden brown, ages to silver grey if left unprotected.

Durability Classification: Class 2 according to BS EN 350-2

Density: 720kg/m3 at a moisture content of 18%

Dimensional Stability: Excellent

Grades: QF-2

Dimensions:

Lengths: 1.8m to 4.0m

Finishing: Accepts application of stains and paints

Working Properties: Can be sawn and planed with standard woodworking equipment. Pre-drilling for fixing location is recommended

Fixing: Austenitic stainless steel fixings are recommended

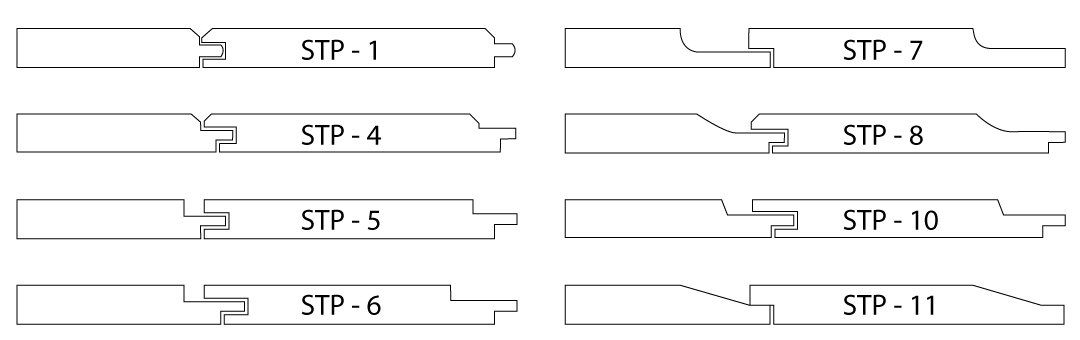

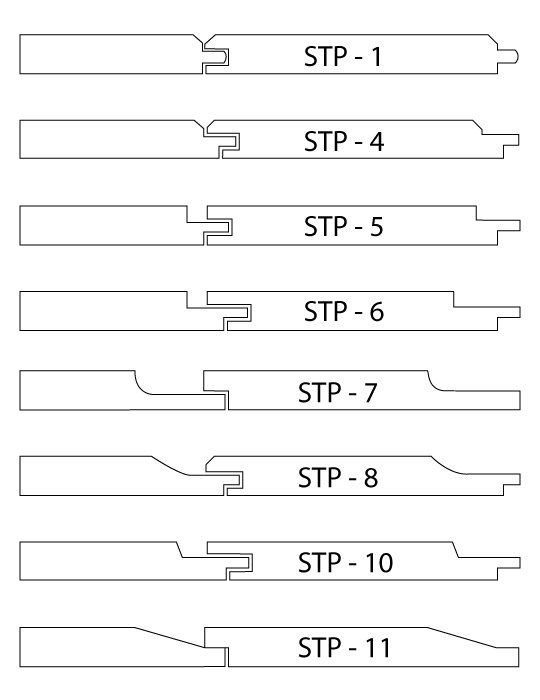

Cladding Profiles

We offer a standard range along with bespoke profiles.

All of our profiles are offered planed as standard, unless otherwise stated.

Further Information

Durability

For external cladding purposes, oak is one of the most durable temperate hardwoods (Class 2 according to BS EN 350-2). As such, it does not require any treatment due to its inherent natural resistance to moisture, decay and insect damage. Although we would estimate that oak cladding has a lifespan of at least 50 years when subject to general outdoor exposure, this is a conservative estimate; it will last for many years more if the cladding is correctly detailed and adequately ventilated.

Dimensional Stability

Our oak is kiln-dried to 16–18% moisture content. The benefit of kiln drying this product, as opposed to air drying, is that the timber dries uniformly and therefore achieves optimum stability. Once the oak is kiln-dried, this enables machining of the product to achieve a superior finish.

Workability

Due to thermal modification process this wood is easy to machine. Ensure that all corners are rounded to prevent splitting.

Fixing

Oak tends to corrode metals due to its acidity, and a black/blue stain can appear in contact with metal. Stainless steel fixings are recommended. Screw fixings should be at least 40mm from the end of the boards to avoid splitting.

Coatings and Treatments

In general Oak finishes well and can be stained or oiled satisfactorily.

Weathering

Oak weathers slowly, eventually turning to a shade of silver/grey - if left untreated over a period of time.

Certification

European Oak cladding is PEFC certified.