Plywood Acoustic Panels

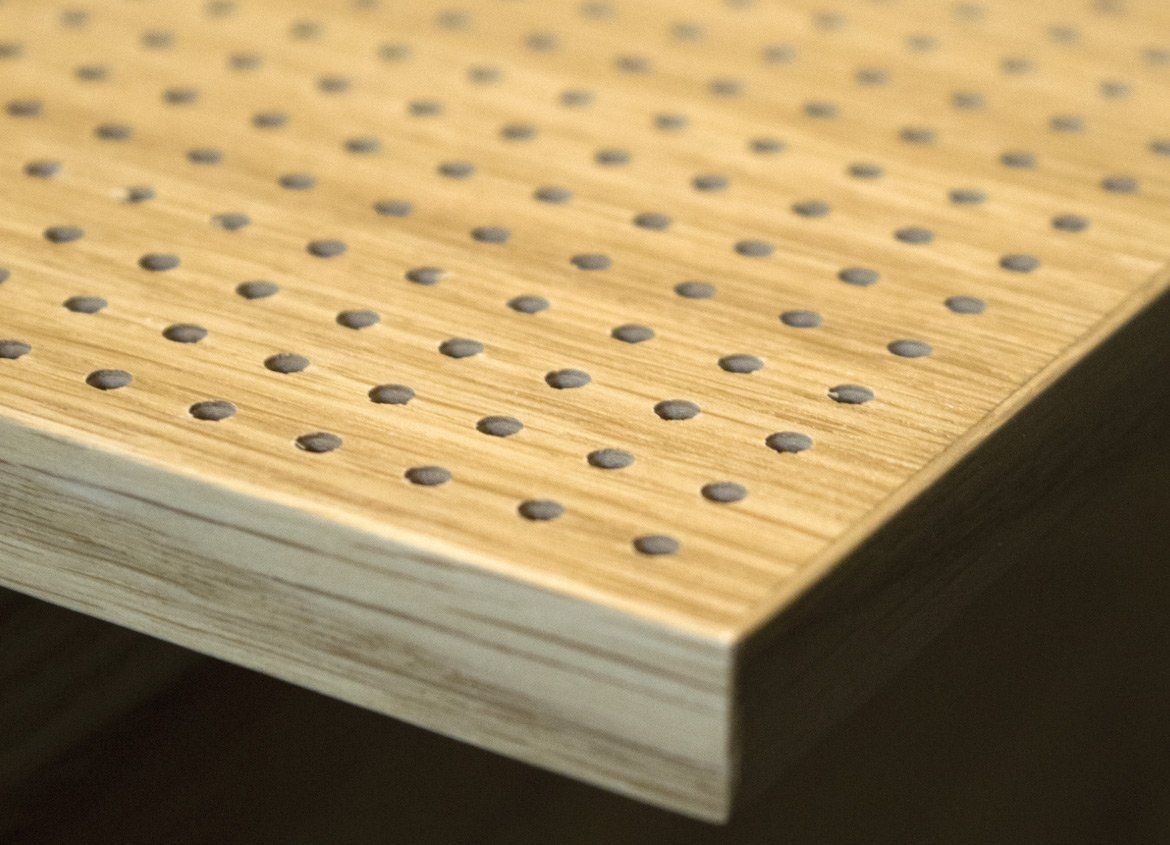

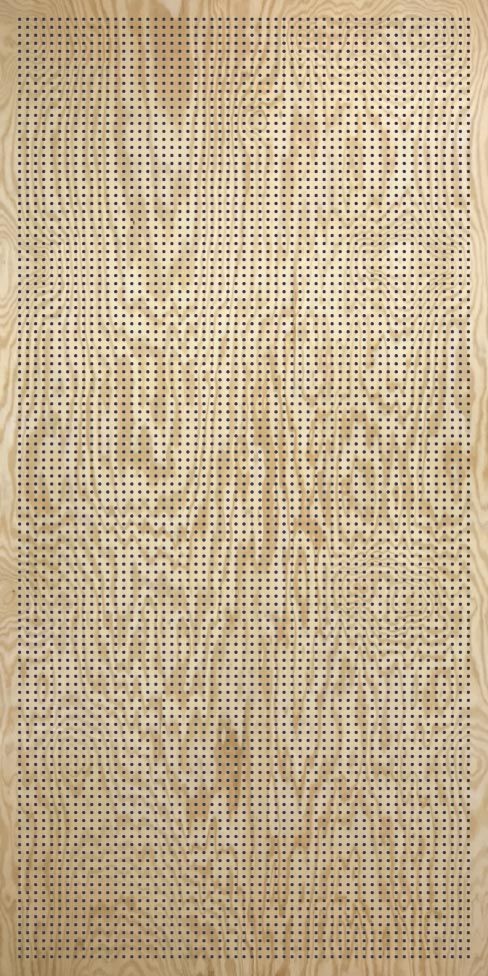

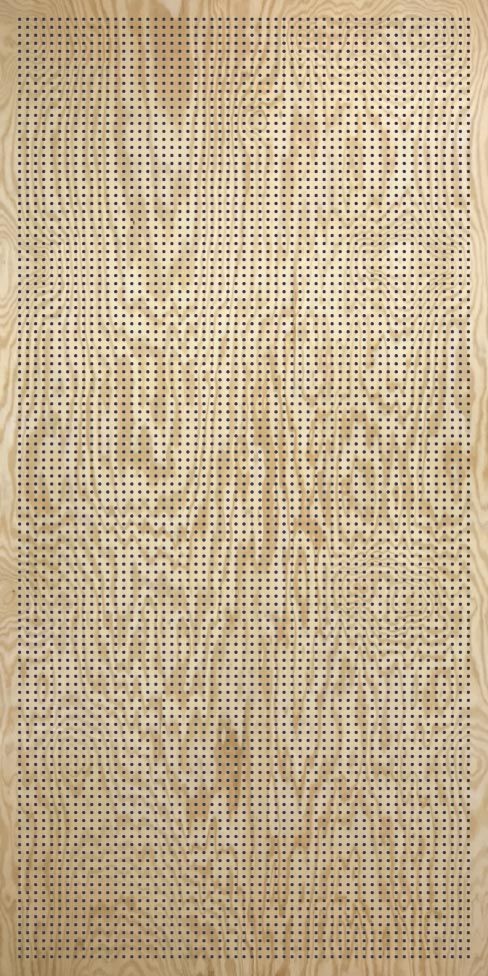

Perforated Plywood

Adjust & Improve Acoustic Levels

Range of Decorative Finishes

Fire Rated Options

Perforated Plywood

Adjust & Improve Acoustic Levels

Range of Decorative Finishes

Fire Rated Options

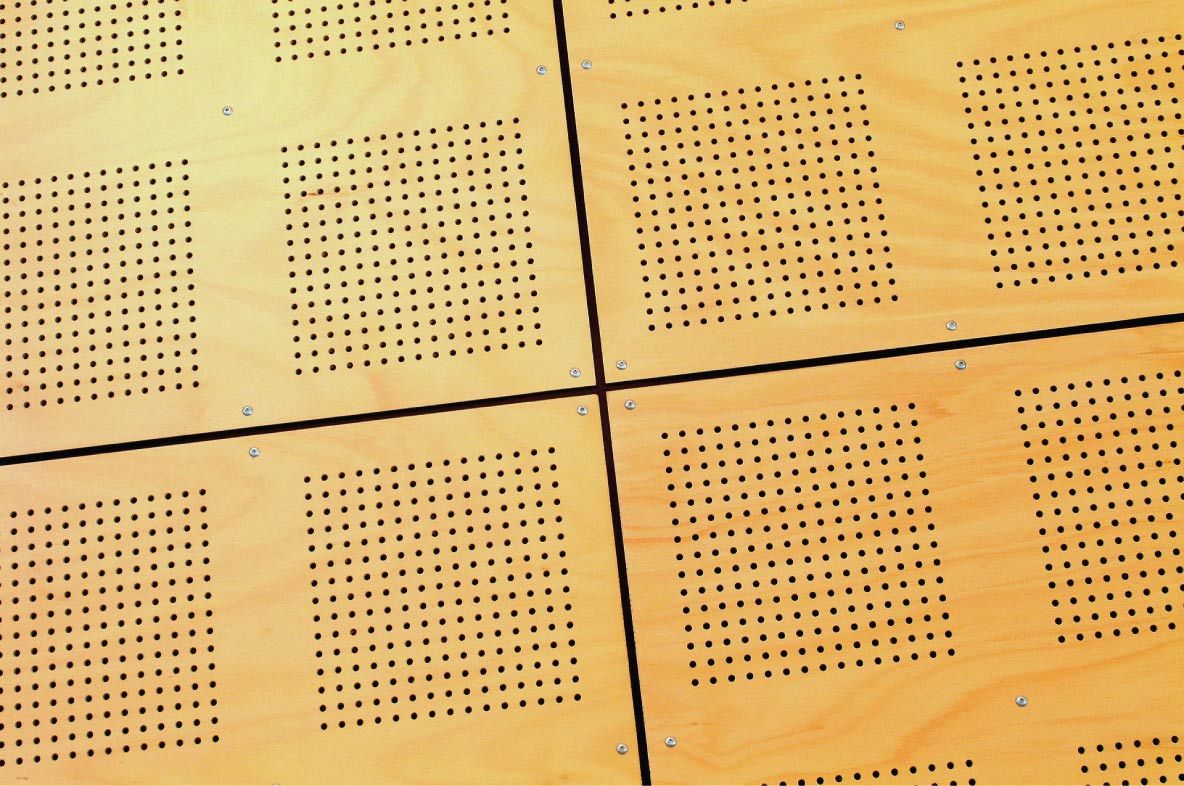

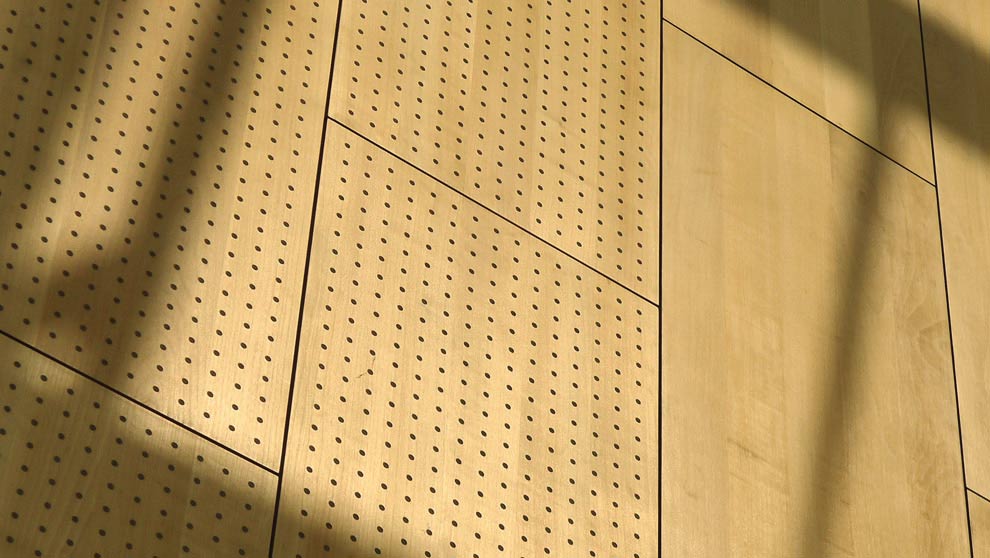

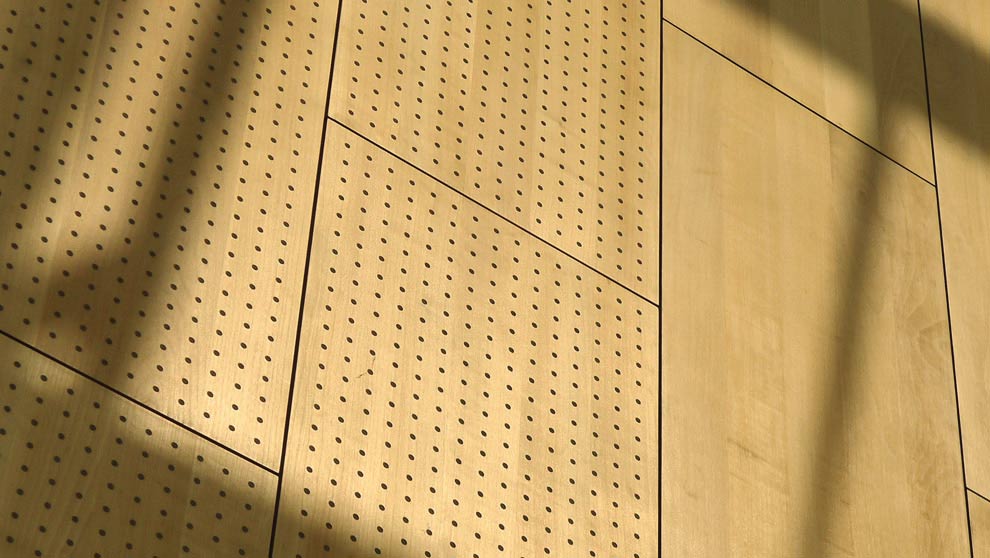

SPP Acoustic panelling is used in a wide variety of environments to adjust, treat and improve the acoustic levels within the area.

Often used within theatres, sports halls, gymnasiums, concert halls and various public spaces, our boards offer a solution to the acoustics, as well as providing a bespoke decorative finish to any room.

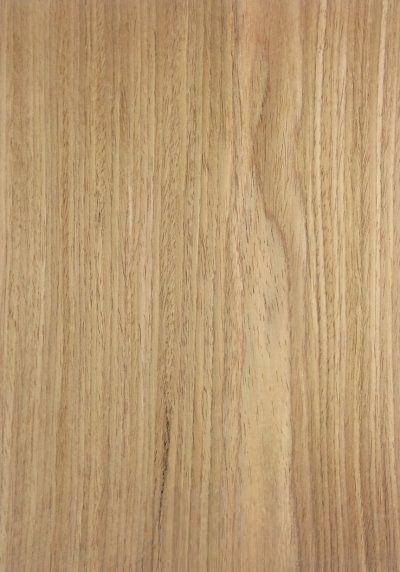

Available in a range of plywood with natural finishes in birch, pine, poplar and beech. Alternatively, our engineered range offers veneers, laminates and melamine finishes.

By combining our acoustic knowledge with joinery expertise we can supply a broad range of specifications and application requirements.

Birch plywood is ideal for sports areas due to its strength and impact resistance

Plywood Acoustic Panels

Perforated Plywood

Adjust & Improve

Acoustic Levels

Range of

Decorative Finishes

Fire Rated Options

Perforated Plywood

Adjust & Improve Acoustic Levels

Range of Decorative Finishes

Fire Rated Options

SPP Acoustic panelling is used in a wide variety of environments to adjust, treat and improve the acoustic levels within the area.

Often used within theatres, sports halls, gymnasiums, concert halls and various public spaces, our boards offer a solution to the acoustics, as well as providing a bespoke decorative finish to any room.

Available in a range of plywood with natural finishes in birch, pine, poplar and beech. Alternatively, our engineered range offers veneers, laminates and melamine finishes.

By combining our acoustic knowledge with joinery expertise we can supply a broad range of specifications and application requirements.

Birch plywood is ideal for sports areas due to its strength and impact resistance

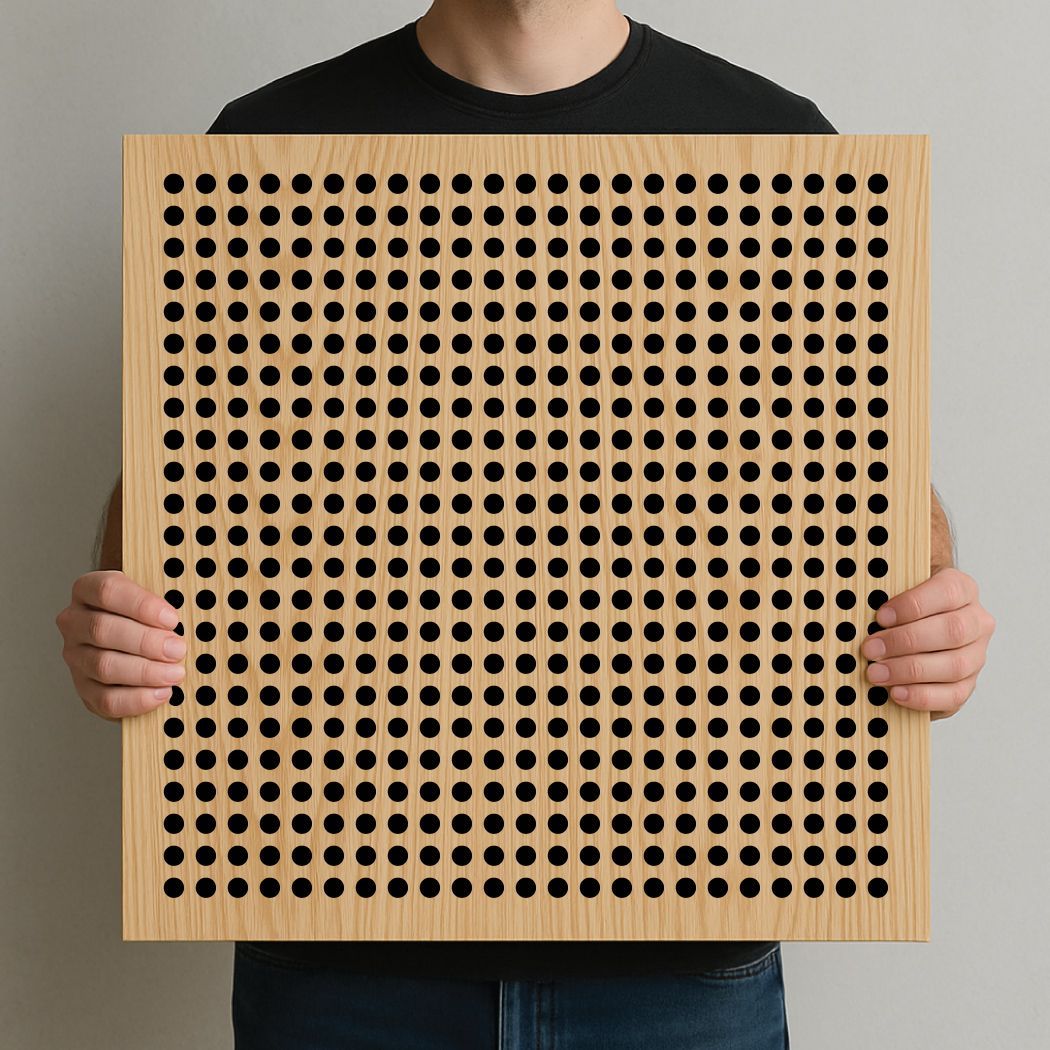

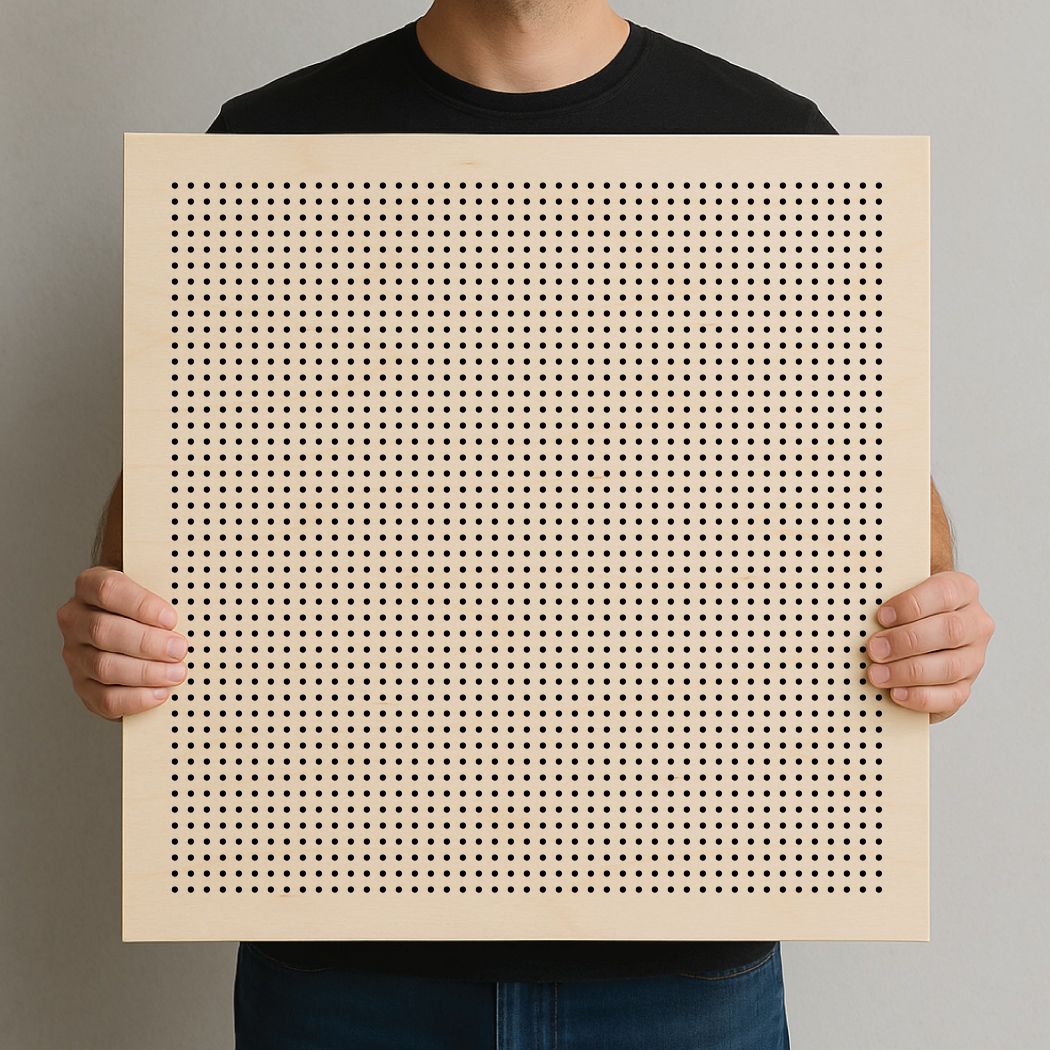

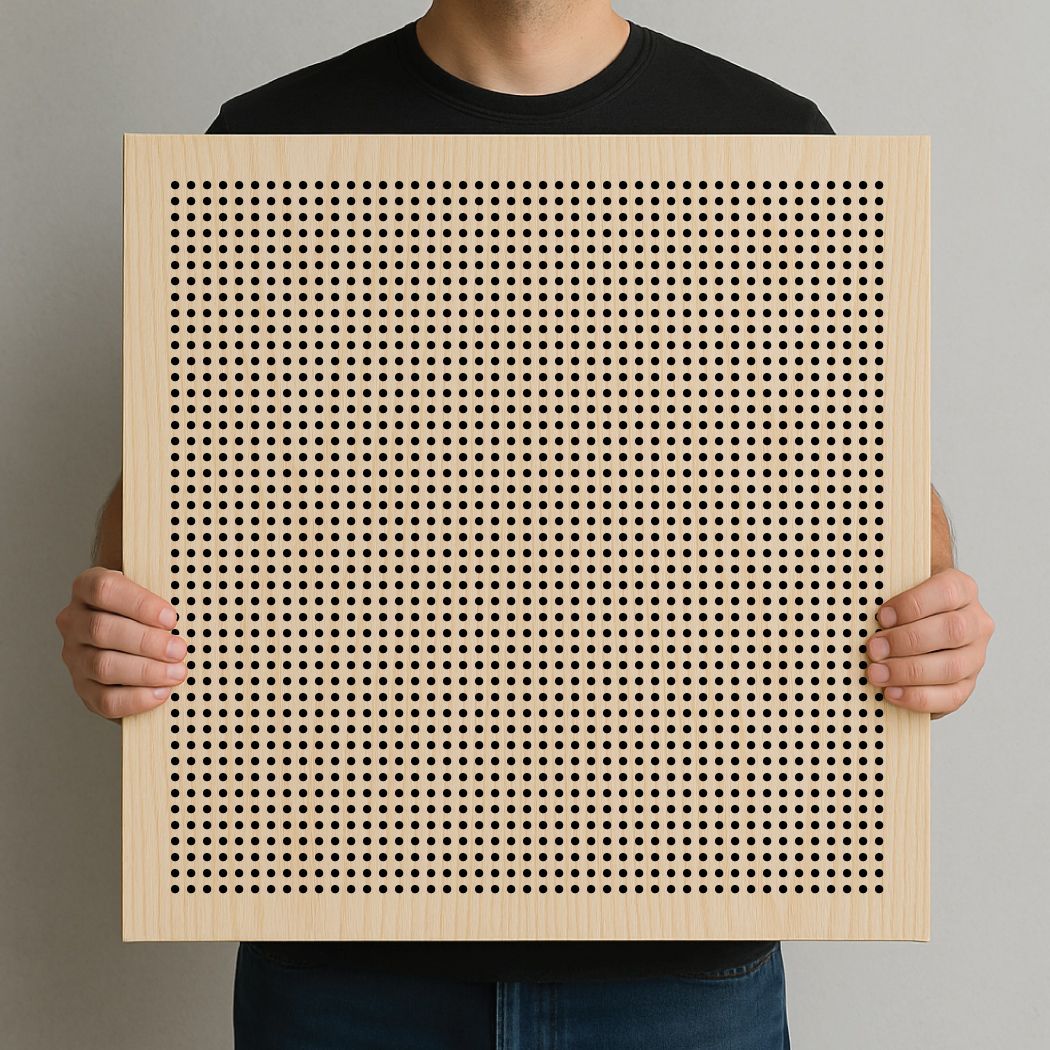

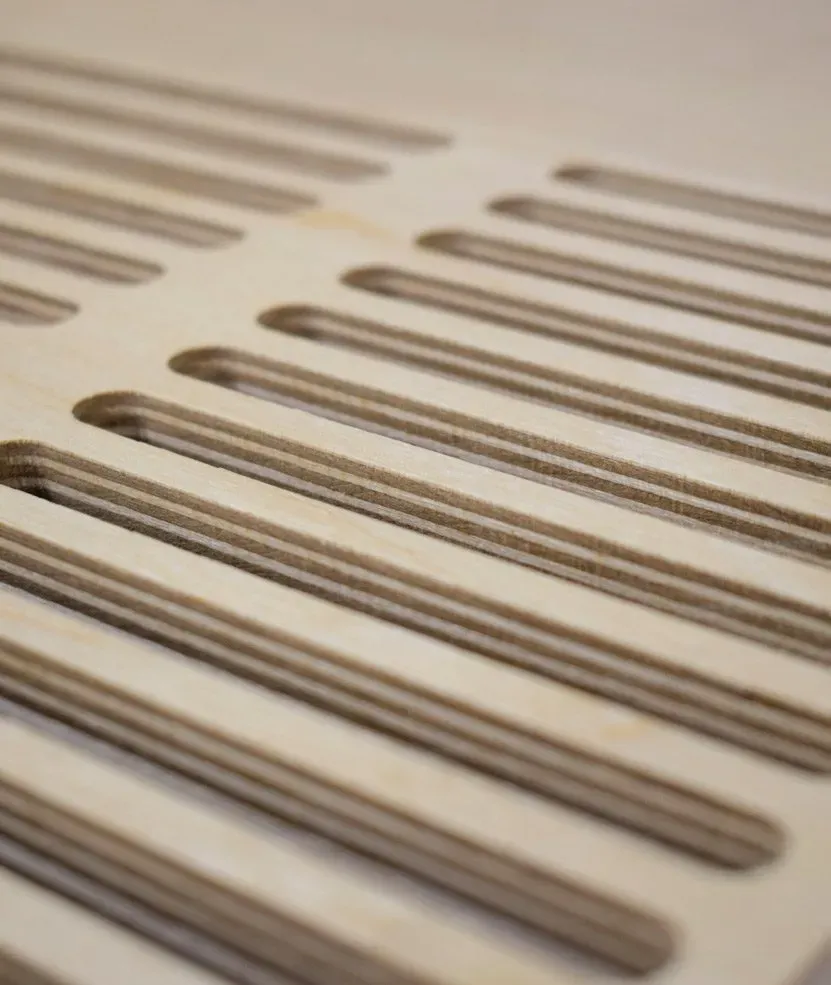

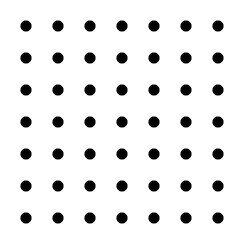

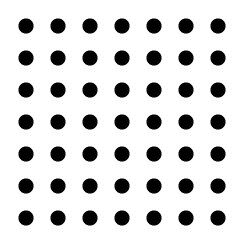

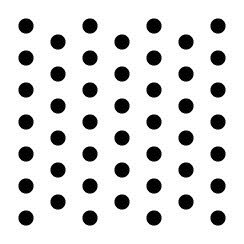

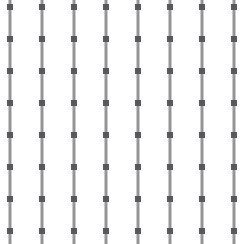

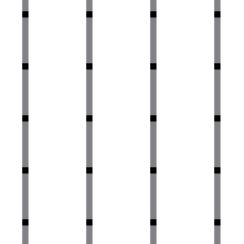

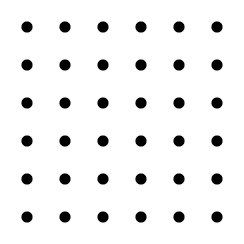

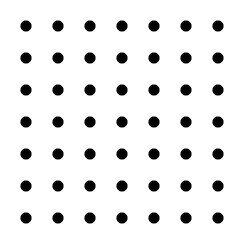

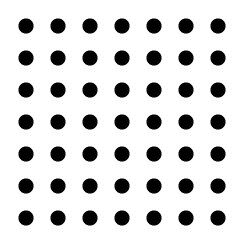

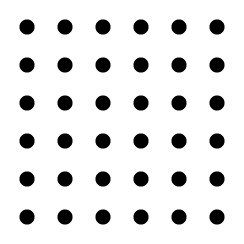

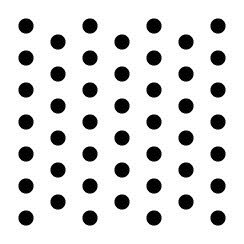

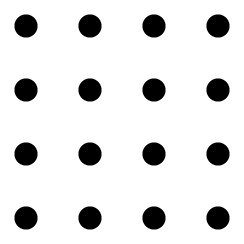

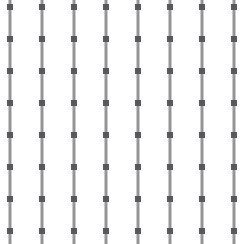

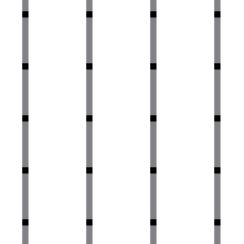

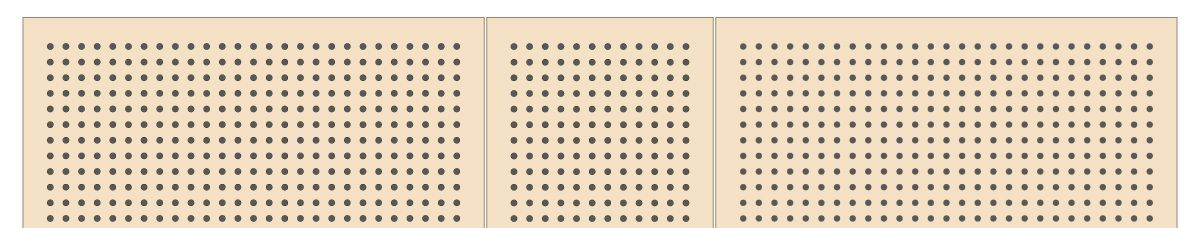

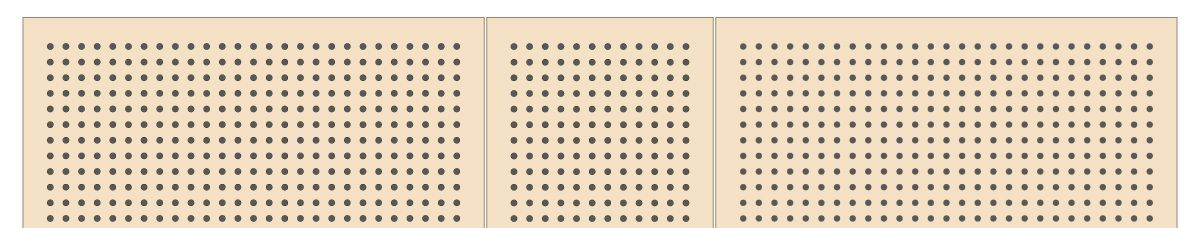

Machining Patterns

We know every project has a different visual and acoustic requirement - requiring both minimum open areas and maximum perforation sizes. We offer a range of standard profiles to cover most project requirements. With our cutting edge machinery we can offer bespoke patterns to suit any specialist need.

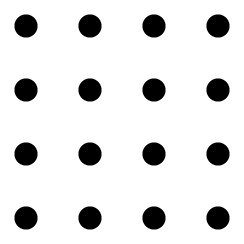

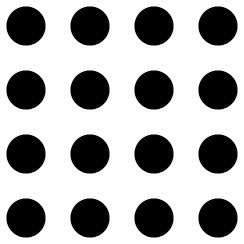

Code: H6-16

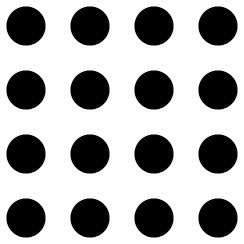

Code: H8-16

Code: H8-16s

Hole Diameter: 6mm

Centres: 16mm

Estimated Open Area: 11%

Hole Diameter: 8mm

Centres: 16mm

Estimated Open Area: 20%

Hole Diameter: 8mm

Centres: 16mm staggered

Estimated Open Area: 10%

Code: H12-32

Code: H20-32

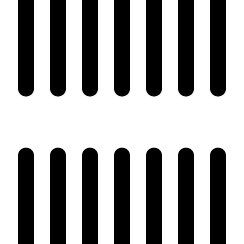

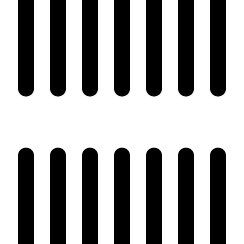

Code: SS8-16

Hole Diameter: 12mm

Centres: 32mm

Estimated Open Area: 11%

Hole Diameter: 20mm

Centres: 32mm

Estimated Open Area: 30%

Slot Width: 8mm

Centres: 16mm

Slot Length: 108mm

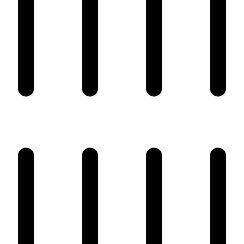

Code: SS8-32

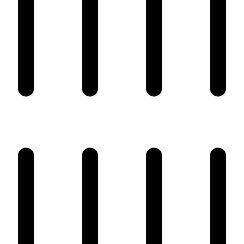

Code: CS3-16

Code: CS3-32

Bespoke

Slot Width 8mm

Centres: 32mm

Slot Length: 108mm

Face Groove: 3mm

Reverse Perforation: 8mm

Centres: 16mm

Face Groove: 3mm

Reverse Perforation: 10mm

Centres: 32mm

Call to discuss

bespoke layouts

Bespoke

Machining Patterns

We know every project has a different visual and acoustic requirement - requiring both minimum open areas and maximum perforation sizes. We offer a range of standard profiles to cover most project requirements. With our cutting edge machinery we can offer bespoke patterns to suit any specialist need.

Code: H6-16

Hole Diameter: 6mm

Centres: 16mm

Estimated Open Area: 11%

Code: H6-18.75

Hole Diameter: 6mm

Centres: 18.75mm

Estimated Open Area: 8%

Code: H8-16

Hole Diameter: 8mm

Centres: 16mm

Estimated Open Area: 20%

Code: H8-18.75

Hole Diameter: 8mm

Centres: 18.75mm

Estimated Open Area: 14%

Code: H8-16s

Hole Diameter: 8mm

Centers: 16mm staggered

Estimated Open Area: 10%

Code: H12-32

Hole Diameter: 12mm

Centres: 32mm

Estimated Open Area: 11%

Code: H20-32

Hole Diameter: 20mm

Centres: 32mm

Estimated Open Area: 30%

Code: SS8-16

Slot Width: 8mm

Centres: 16mm

Slot Length: 108mm

Code: SS8-32

Slot Width: 8mm

Centres: 32mm

Slot Length: 108mm

Code: CS3-16

Face Groove: 3mm

Reverse Perf: 8mm

Centres: 16mm

Code: SS8-32

Sloth Width: 8mm

Centres: 32mm

Slot Length: 108mm

Contact us to discuss

bespoke machining

Bespoke

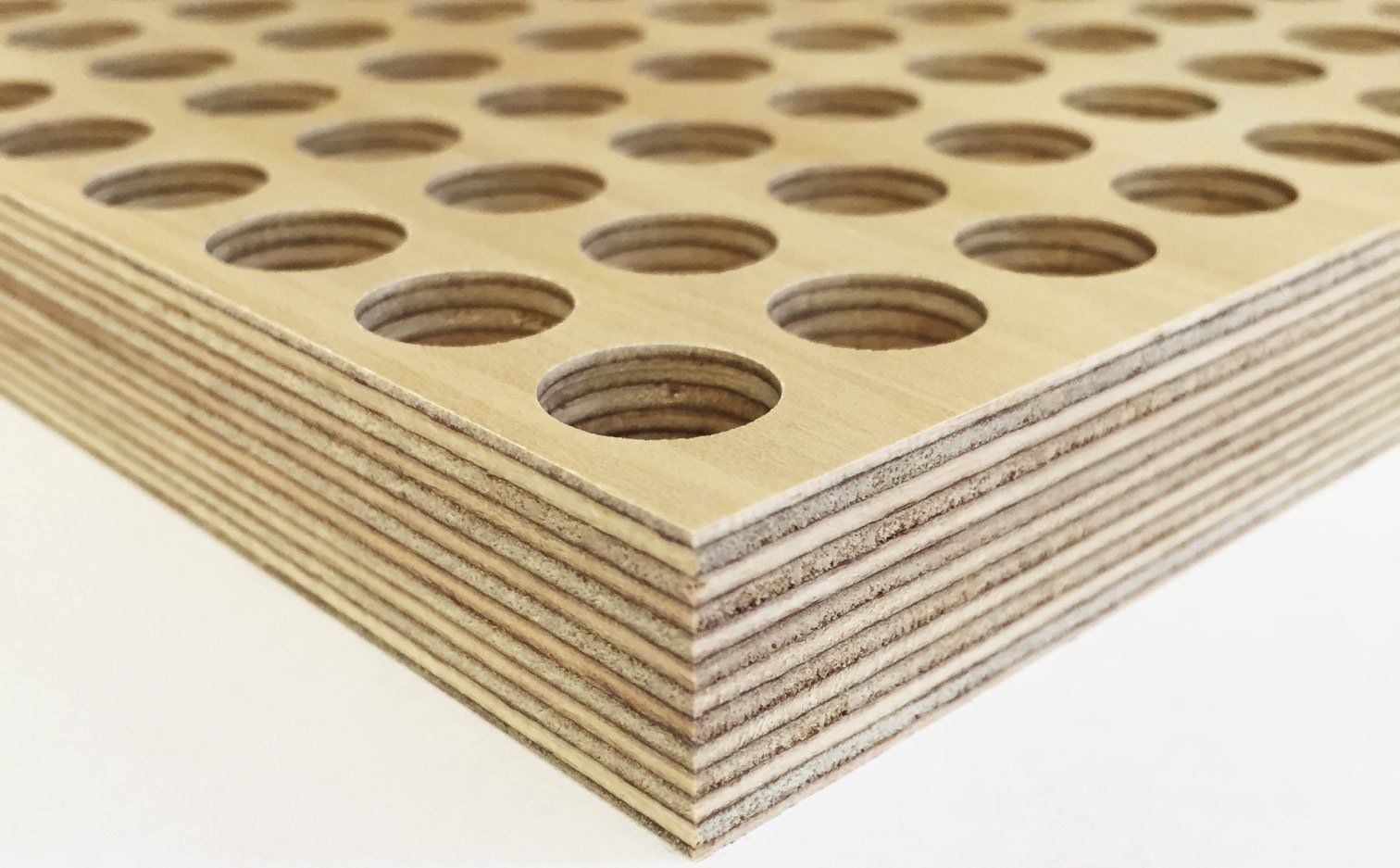

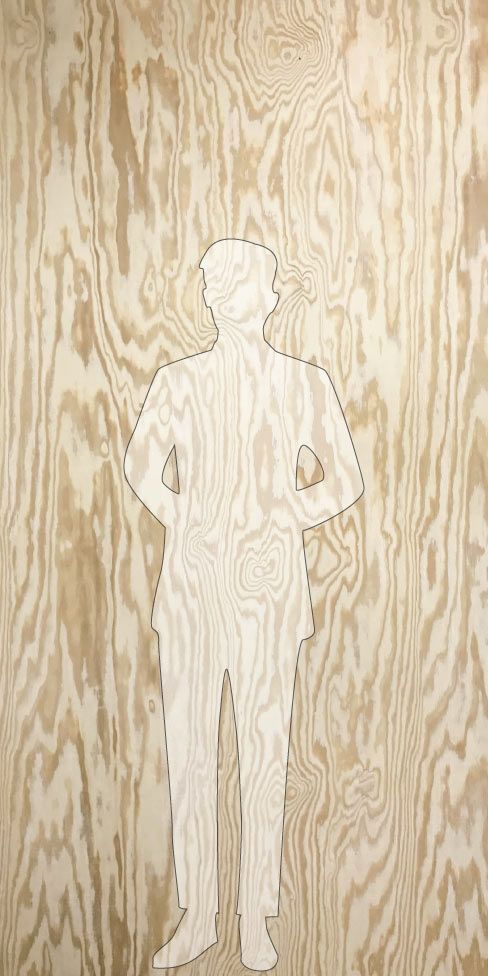

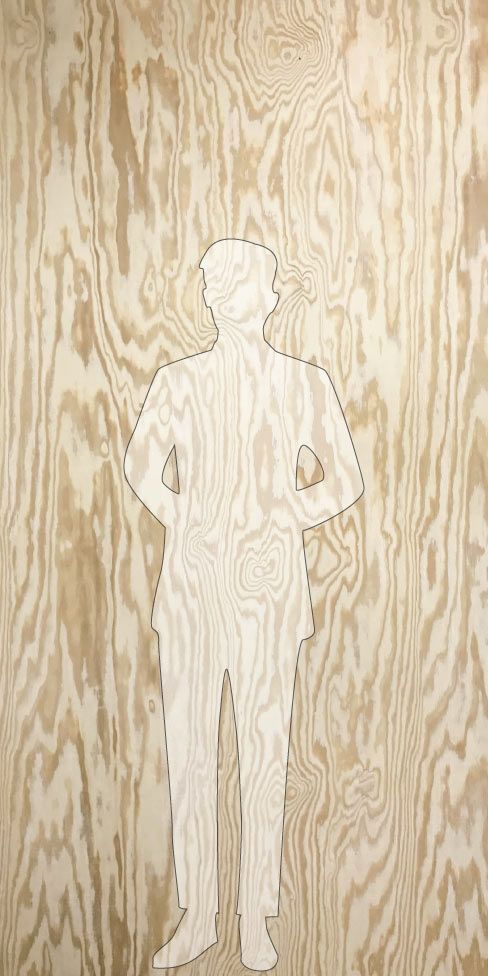

Panels

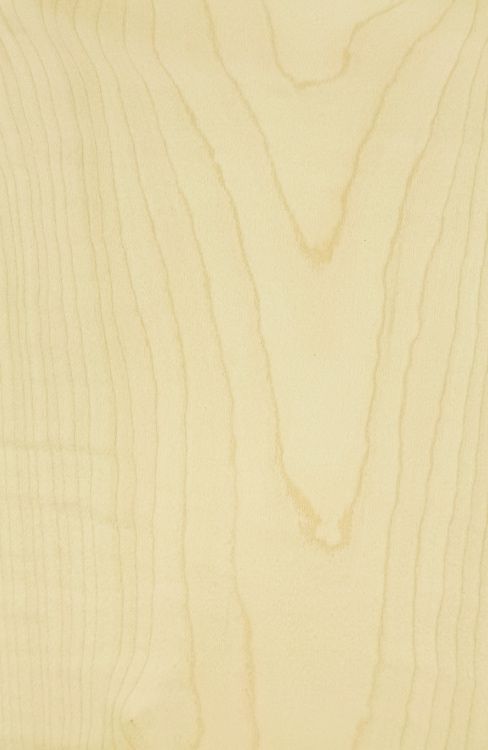

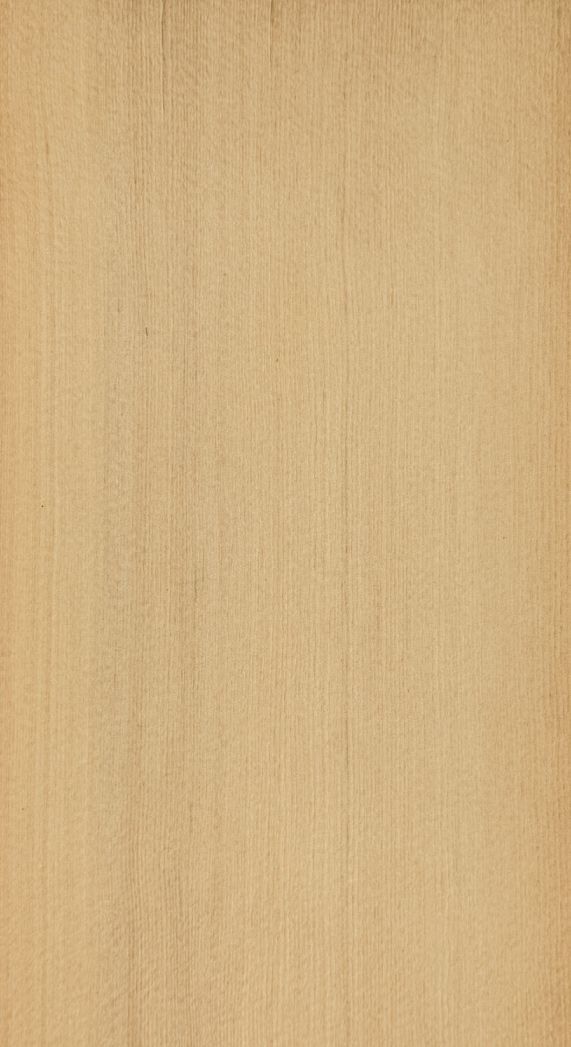

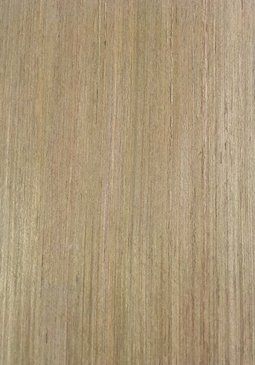

Birch Plywood

European birch throughout plywood. A plain, light coloured panel with excellent strength. High quality face veneers produced to an environmentally friendly standard.

Face Grades

B Grade: high quality grade that presents a clean face with few natural variations minimal plugs/patches. Limited availability.

Fine-Stipe: Birch core overlaid with strip birch veneers to provide a clean, plug free and knot free face.

BB grade: unseen, reverse panel side with plugs/patches and other variations permitted.

Our Birch Plywood Specifications Page has more details on face grading rules.

Popular applications are Sports Halls, Lecture Theatres, Reception Areas and Retail Spaces.

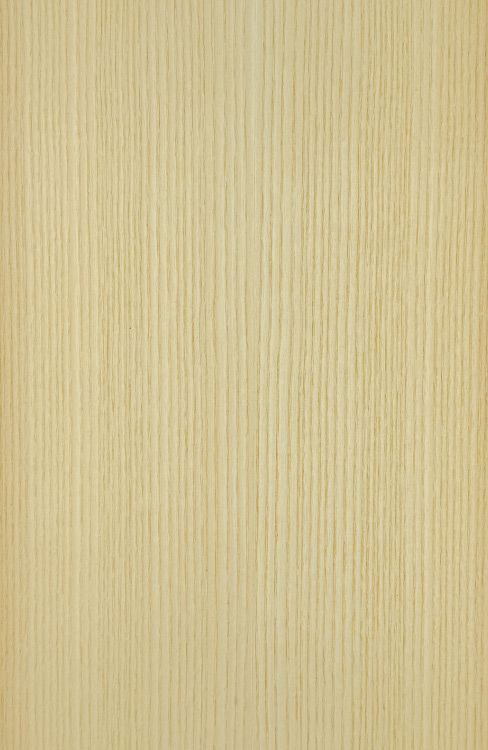

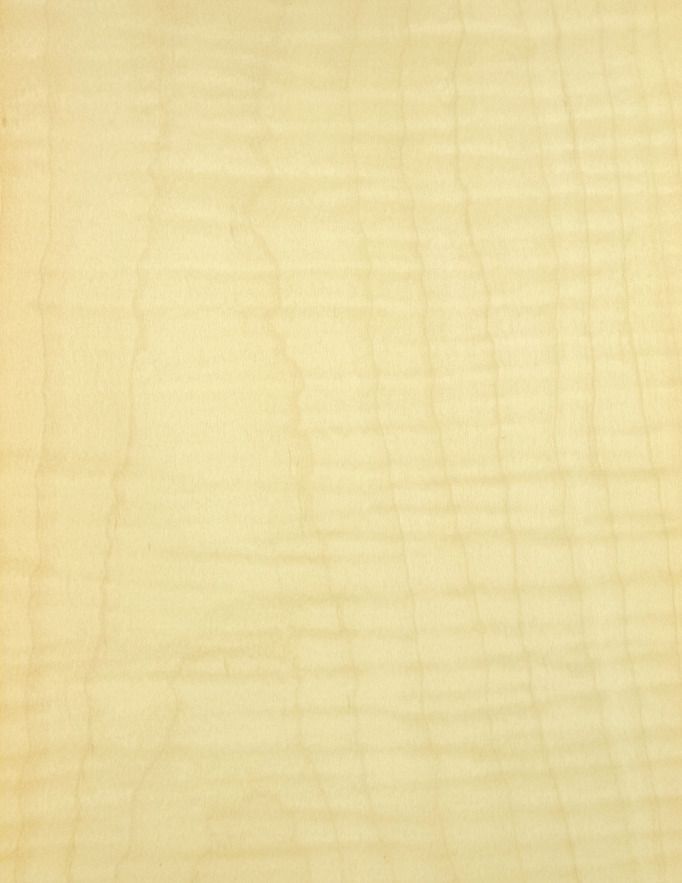

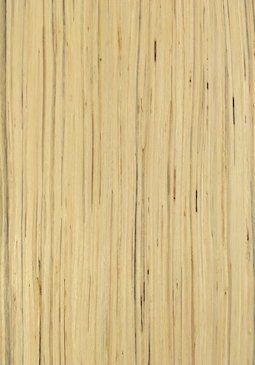

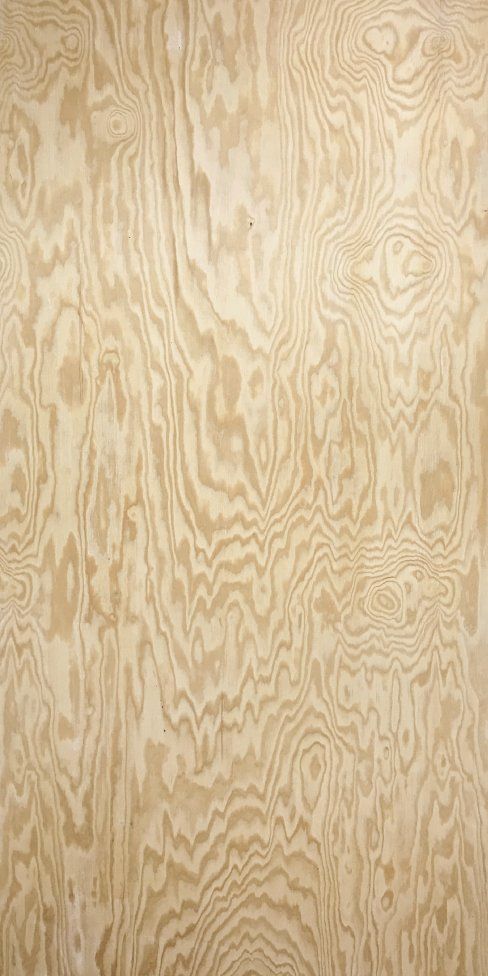

Decorative Pine Plywood

European pine plywood

An attractive, decorative panel

Expertly specified and manufactured

High grade rotary cut faces

Carefully made core construction

Face: I grade

No filler and minimal plugs

Reverse: II grade

More rustic, allowing knots, plugs and filler

We veneer onto plywood or MDF

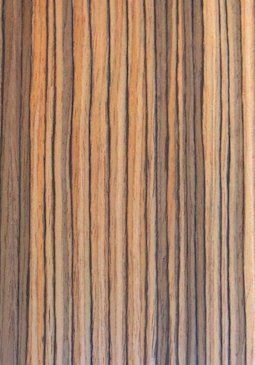

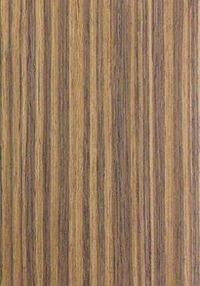

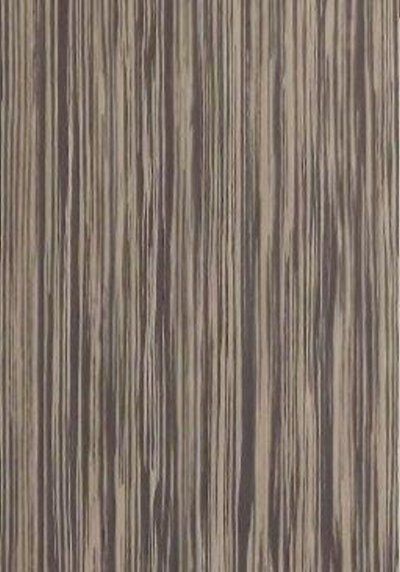

Our standard range offers a cost-effective option and is shown below. Finished by our veneering factory, each of our veneer options are carefully selected to meet customer requirements. For projects requiring consistent colour and grain pattern between panels we offer a selection service where veneers are expertly matched by hand.

From original concept to final production, we ensure all parties are happy and expectations are exceeded.

Popular applications include Lecture Theatres, Hotel Lobby and Reception, Meeting Rooms, Offices.

Euro Oak

Quarter Cut

Euro Oak

Crown Cut

White Oak

Quarter Cut

Red Oak

Crown Cut

Pippy Oak

Crown Cut

Character Oakchara

Random Matched

Bronze Oak

Crown Cut

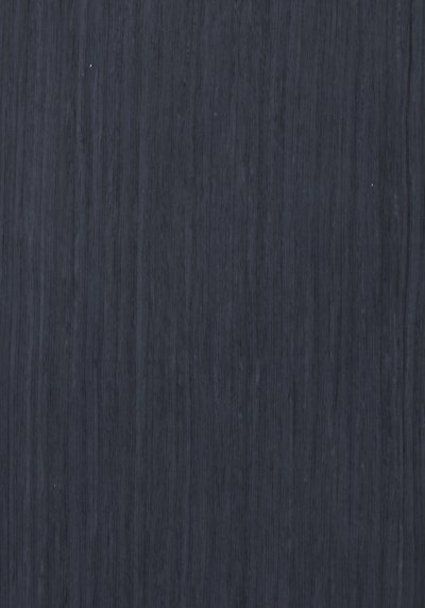

Smoked Oak

Quarter Cut

Ash

Crown Cut

Ash

Quarter Cut

Birch

Rotary Cut

White Beechwhite-be

Crown Cut

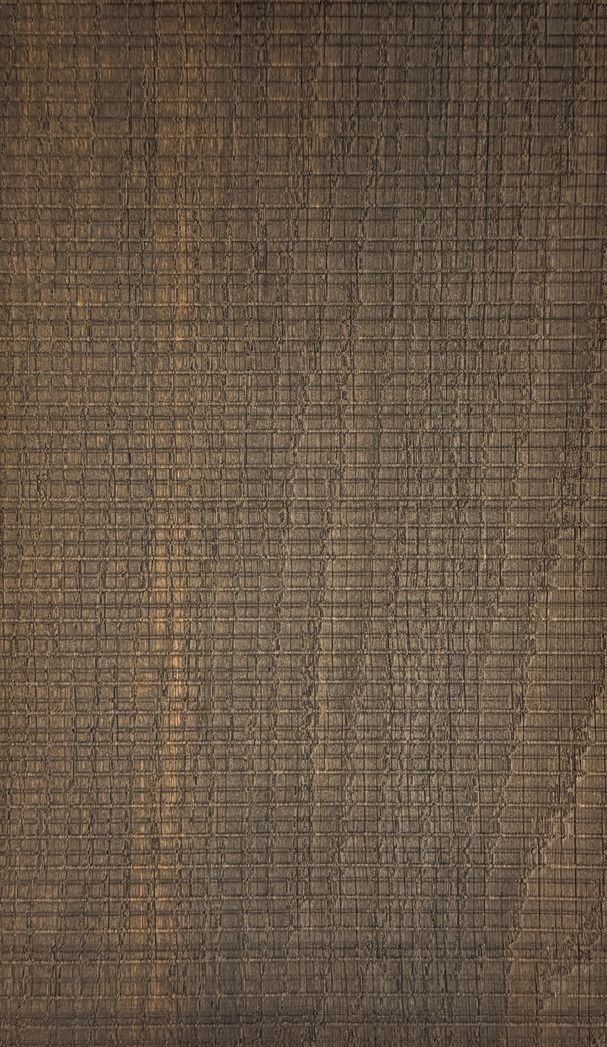

Real Wood Veneers

Textured Oak Crown

Embossed Surface

Textured Oak Quarter

Embossed Surface

Textured Oak Rustic

Embossed Surface

Textured Oak Smoked

Embossed Surface

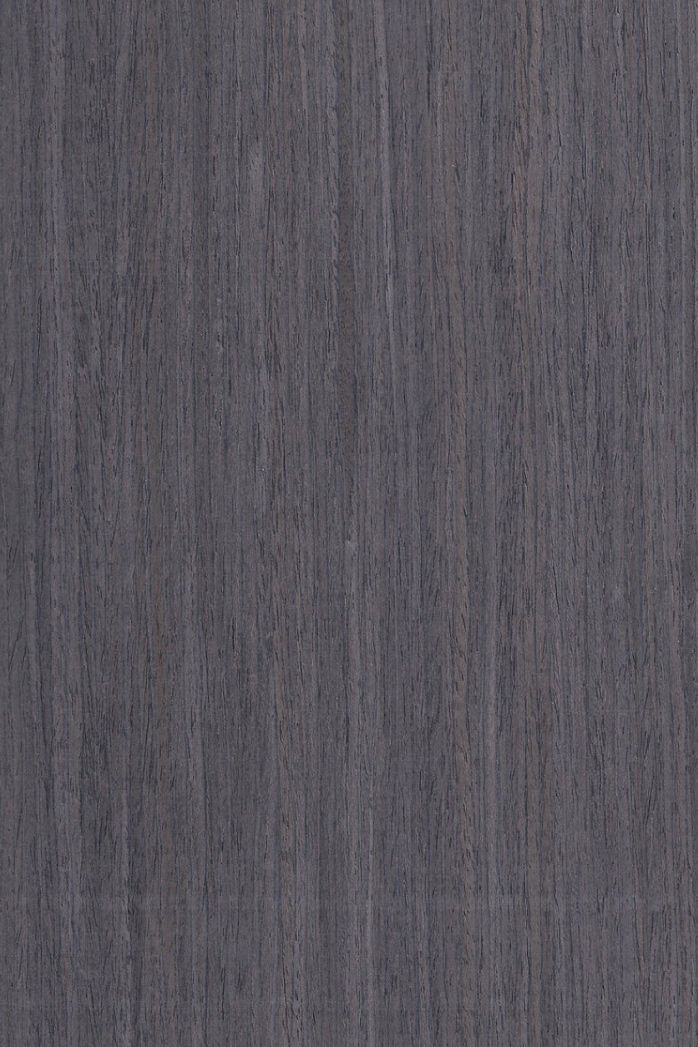

Oak Grey 1

Dyed Veneer

Oak EV Silver

Engineered Veneer

Oak Silvered Flakey

Dyed Veneer

Oak Brown 1

Dyed Veneer

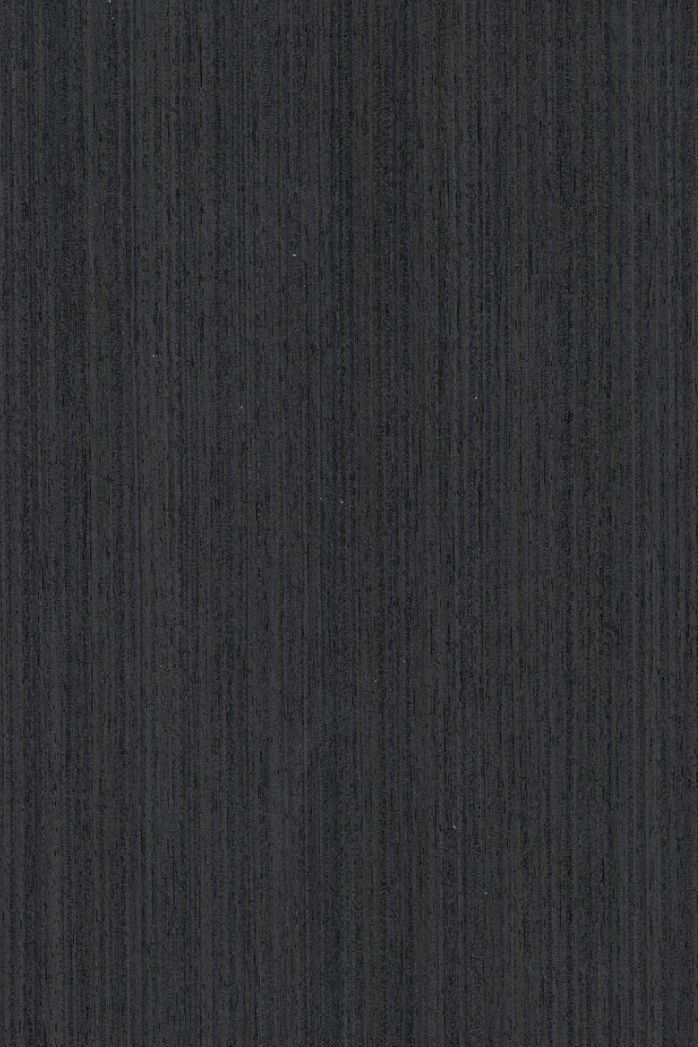

Oak Black 1

Dyed Veneer

Oak EV Black 1

Engineered Veneer

Oak EV Black 2

Engineered Veneer

Eucalyptus Grey 1

Dyed, Figured & Iridescent

Eucalyptus Grey 2

Dyed, Figured & Iridescent

Eucalyptus Grey 3

Dyed, Figured & Iridescent

Eucalyptus Grey 4

Dyed, Figured & Iridescent

Eucalyptus Grey 5

Dyed Veneer

Eucalyptus Silvered

Dyed, Figured & Iridescent

Eucalyptus Smoked 1

Dyed Veneer

Eucalyptus Smoked 2

Dyed Veneer

Olive Ash Crown

Crown Cut

Olive Ash Quarter

Quarter Cut

Ash Pastel

Dyed, Crown Cut

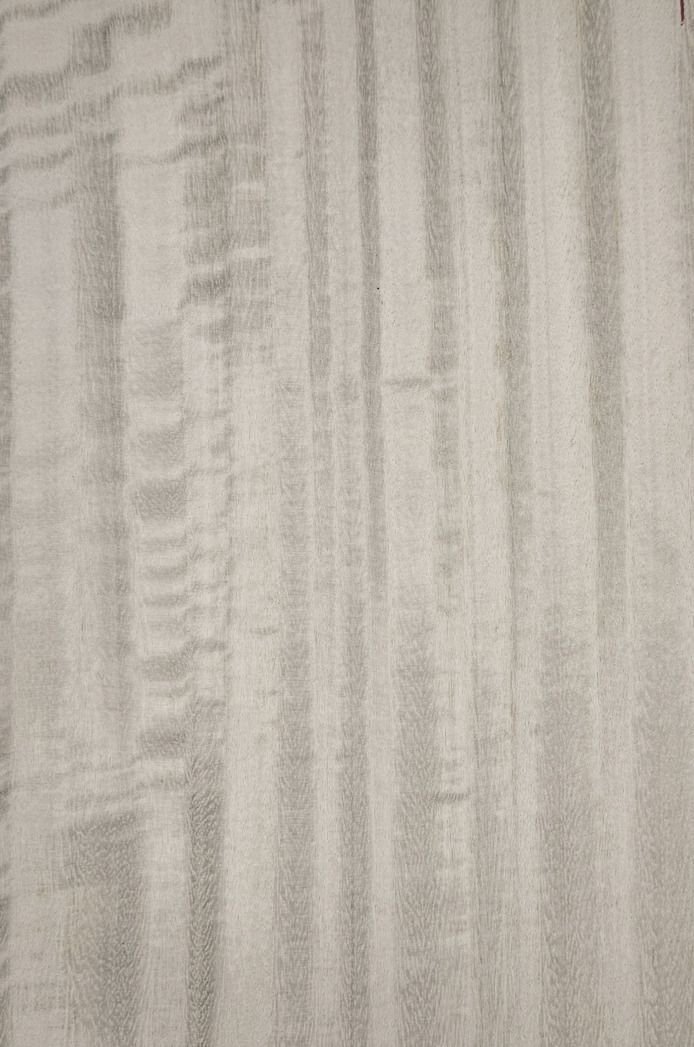

Ash Grey 1

Dyed, Crown Cut

Ash Grey 2

Dyed, Crown Cut

Ash Grey 3

Dyed, Crown Cut

Ash Textured Grey

Embossed Surface

Ash Brown

Dyed, Crown Cut

Ash Black Brown

Dyed, Crown Cut

Ash Black

Dyed, Crown Cut

Koto Grey 1

Dyed, Quarter Cut

Koto Grey 2

Dyed, Quarter Cut

Tulipwood Grey 1

Dyed, Crown Cut

Tulipwood Grey 2

Dyed, Crown Cut

Onyx

Engineered Veneer

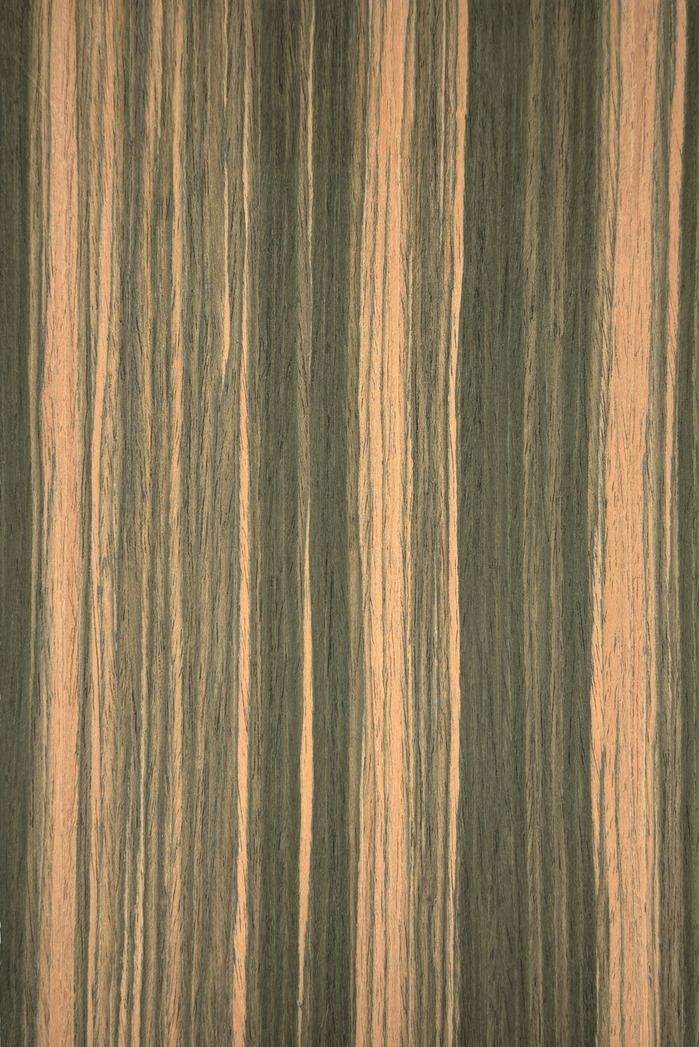

Ebony EV

Engineered Veneer

Ebony

Natural Veneer

Chestnut Crown

Crown Cut

Chestnut Quarter

Quarter Cut

Lebanon Cedar

Crown Cut

Grey Elm

Crown Cut

Red Elm

Crown Cut

Larch

Crown Cut

Smoked Larch

Dyed, Quarter Cut

Santos Rosewood

Crown Cut

Rosewood EV

Engineered Veneer

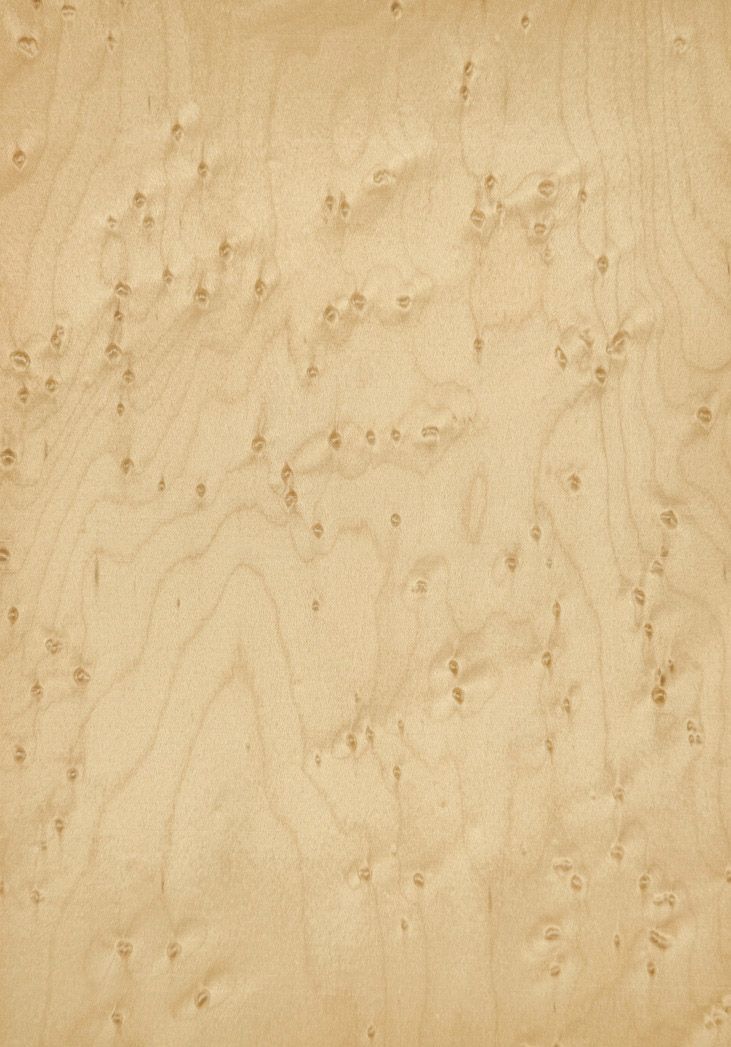

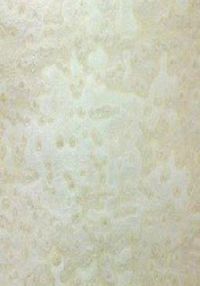

Birds Eye Maple

Natural Veneer

Bamboo Natural

Plain Pressed

Bamboo Carbonised

Plain Pressed

Oregon Pine

Quarter Cut

Wenge Crown

Crown Cut

Wenge Quarter

Quarter Cut

Louro Preto

Crown Cut

Louro Faia Smoked

Quarter Cut, Fumed

Tineo Quarter

Quarter Cut

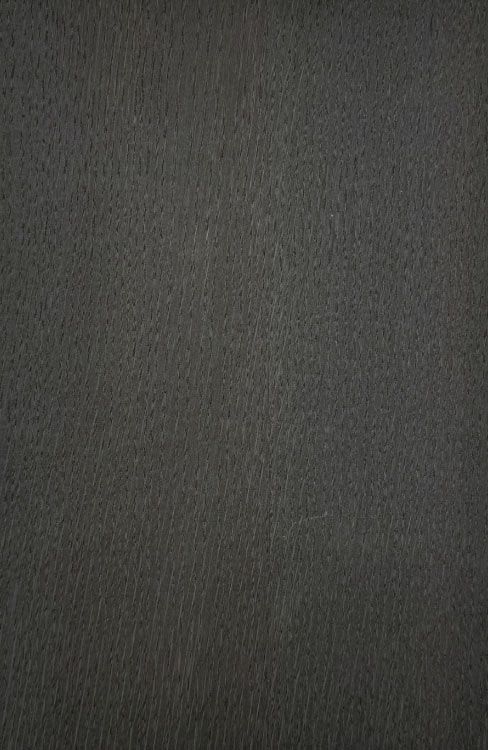

Engineered Veneers (EV)

EV is poplar or basswood timber, stained to mimic other species

For projects requiring a very consistent finish with limited variation allowed on the specification

Hundreds of styles available

Laminates

Panel Sizes

As most projects are bespoke, we can offer any cut-size you require

To reduce wastage and unnecessary cost, we suggest the majority of panels are made up from the sizes below

All panel edges are trimmed first to improve dimensional tolerances, ensuring uniformity and straightness over a wide span of panels

As most projects are bespoke, we can offer any cut-size you require

To reduce wastage and unnecessary cost, we suggest the majority of panels are made up from the sizes below

All panel edges are trimmed first to improve dimensional tolerances, ensuring uniformity and straightness over a wide span of panels

* 1600mm is the maximum width for machined or perforated panels

Solid MDF core panels can be offered up to 3600 x 1800

High pressure laminate bonded to plywood or fibreboard.

Robust and consistent finish.

Hundreds of options:

- Plain colours

- Wood-grain

- Stone effect

- Metals

.

Plywood/MDF

Plywood

MDF

MDF

Original Size

2440 x 1220

1525 x 3050

3050 x 1220

3660 x 1830

Full Size

2400 x 1200

1500 x 3000

3000 x 1200

3600 x 1600*

Half Size 1

1200 x 1200

1500 x 1500

1500 x 1200

1800 x 1600*

Half Size 2

2400 x 600

750 x 3000

3000 x 600

3600 x 800

Quarter Size

1200 x 600

750 x 1500

1500 x 600

1800 x 800

Panels

Birch Plywood

European birch throughout plywood. A plain, light coloured panel with excellent strength. High quality face veneers produced to an environmentally friendly standard.

Face Grades

B Grade: high quality grade that presents a clean face with few natural variations minimal plugs/patches. Limited availability.

Fine-Stipe: Birch core overlaid with strip birch veneers to provide a clean, plug free and knot free face.

BB grade: unseen, reverse panel side with plugs/patches and other variations permitted.

Our Birch Plywood Specifications Page has more details on face grading rules.

Popular applications are Sports Halls, Lecture Theatres, Reception Areas and Retail Spaces.

Decorative

Pine Plywood

European pine plywood

An attractive, decorative panel

Expertly specified and manufactured

High grade rotary cut faces

Carefully made core construction

Face: I grade

No filler and minimal plugs

Reverse: II grade

More rustic, allowing knots, plugs and filler

We veneer onto plywood or MDF

Our standard range offers a cost-effective option and is shown below. Finished by our veneering factory, each of our veneer options are carefully selected to meet customer requirements. For projects requiring consistent colour and grain between panels we offer a selection service where veneers are expertly matched by hand.

From original concept to final production, we will ensure all parties are happy and expectations are exceeded.

Popular applications include Lecture Theatres, Hotel Lobby and Reception, Meeting Rooms, Offices.

Euro Oak

Quarter Cut

Euro Oak

Crown Cut

White Oak

Quarter Cut

Red Oak

Crown Cut

Pippy Oak

Crown Cut

Character Oak

Random Matched

Bronze Oak

Crown Cut

Smoked Oak

Quarter Cut

Ash

Crown Cut

Ash

Quarter Cut

Birch

Rotary Cut

White Beech

Crown Cut

Real Wood Veneers

Textured Oak

Natural Veneer

Crown Cut

Embossed Surface

Textured & Ridged

Textured Oak Rustic

Natural Veneer

Crown Cut

Embossed Surface

Textured & Ridged

Textured Oak Smoked

Natural Veneer

Crown Cut

Embossed Surface

Textured & Ridged

Oak Grey 1

Natural Veneer

Dyed

Quarter Cut

Oak Silvered Flakey

Natural Veneer

Dyed

Quarter Cut

Oak Brown 1

Natural Veneer

Dyed

Quarter Cut

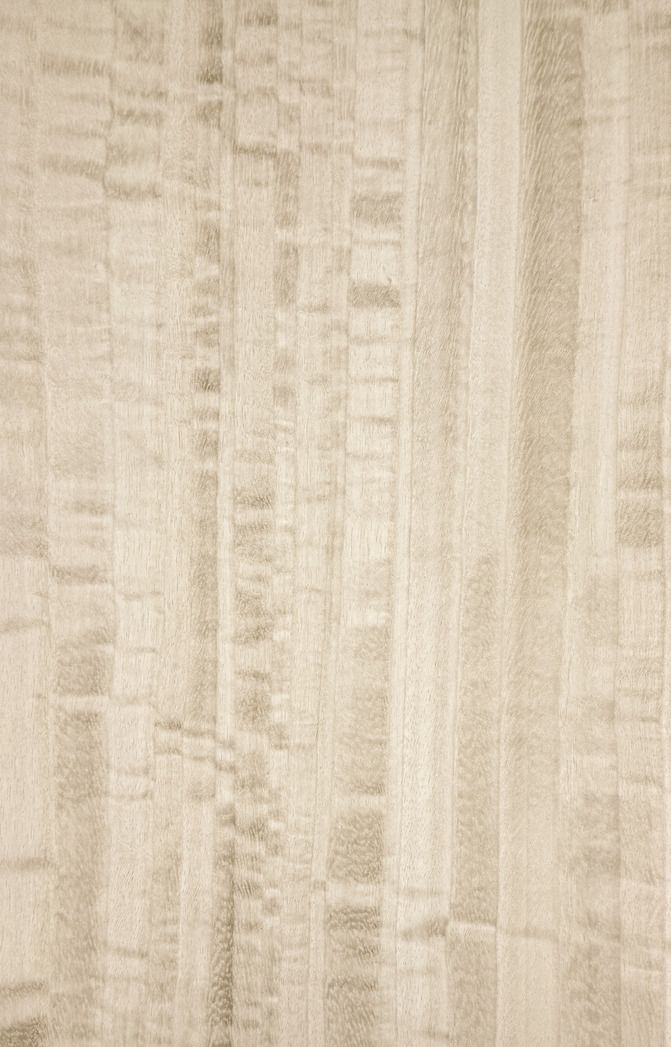

Eucalyptus Grey 1

Natural Veneer

Dyed

Figured

High Iridescence

Eucalyptus Grey 2

Natural Veneer

Dyed

Figured

High Iridescence

Eucalyptus Grey 3

Natural Veneer

Dyed

Figured

High Iridescence

Eucalyptus Silvered

Natural Veneer

Dyed

Figured

High Iridescence

Koto Grey 1

Natural Veneer

Dyed

Quarter Cut

Some Iridescence

Koto Grey 2

Natural Veneer

Dyed

Quarter Cut

Tulipwood Grey 1

Natural Veneer

Dyed

Crown Cut

Tulipwood Grey 2

Natural Veneer

Dyed

Crown Cut

Olive Ash

Natural Veneer

Crown Cut

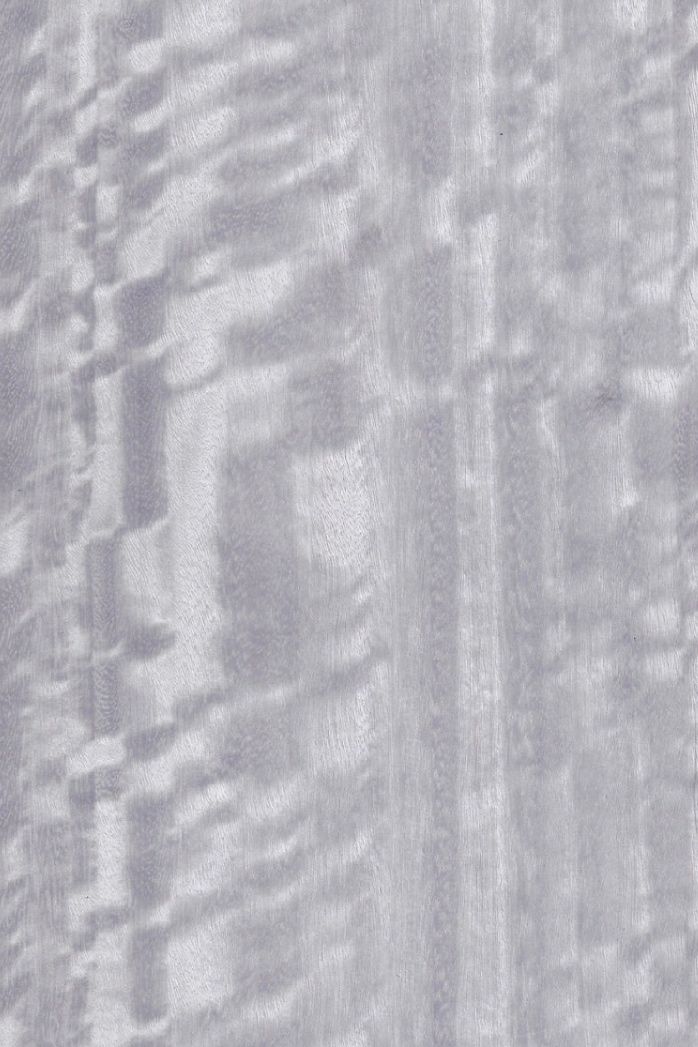

Ash Pastel

Natural Veneer

Dyed

Crown Cut

Ash Grey 1

Natural Veneer

Dyed

Crown Cut

Ash Grey 2

Natural Veneer

Dyed

Crown Cut

Ash Grey 3

Natural Veneer

Dyed

Crown Cut

Ash Brown

Natural Veneer

Dyed

Crown Cut

Ash Black Brown

Natural Veneer

Dyed

Crown Cut

Ash Black

Natural Veneer

Dyed

Crown Cut

Onyx

Engineered Veneer

"Crown Cut" Pattern

Ebony EV

Engineered Veneer

Ebony

Natural Veneer

Chestnut

Natural Veneer

Crown Cut

Chestnut

Natural Veneer

Quarter Cut

Lebanon Cedar

Natural Veneer

Crown Cut

Grey Elm

Natural Veneer

Crown Cut

Red Elm

Natural Veneer

Crown Cut

Engineered Veneers (EV)

EV is poplar or basswood timber, stained to mimic other species. For projects requiring a very consistent finish with limited variation allowed on the specification.

Hundreds of styles available

Laminates

Panel Sizes

As most projects are bespoke

we can offer any cut-size you require

To reduce wastage and unnecessary cost, we suggest the majority of panels are made up from the sizes below

All panel edges are trimmed first to improve dimensional tolerances, ensuring uniformity and straightness over a wide span of panels

| Plywood / MDF | Panel Sizes |

|---|---|

| Original Size | 2440 x 1220 |

| Full Size | 2400 x 1200 |

| Half Size 1 | 1200 x 1200 |

| Half Size 2 | 2400 x 600 |

| Quarter Size | 1200 x 600 |

| Plywood | Panel Sizes |

|---|---|

| Original Size | 1525 x 3050 |

| Full Size | 1500 x 3000 |

| Half Size 1 | 1500 x 1500 |

| Half Size 2 | 750 x 3000 |

| Quarter Size | 750 x 1500 |

| MDF | Panel Sizes |

|---|---|

| Original Size | 3050 x 1220 |

| Full Size | 3000 x 1200 |

| Half Size 1 | 1500 x 1200 |

| Half Size 2 | 3000 x 600 |

| Quarter Size | 1500 x 600 |

| MDF | Panel Sizes |

|---|---|

| Original Size | 3660 x 1830 |

| Full Size | 3600 x 1600* |

| Half Size 1 | 1800 x 1600* |

| Half Size 2 | 3600 x 800 |

| Quarter Size | 1800 x 800 |

* 1600mm is the maximum width

for machined or perforated panels

Solid MDF core panels can be offered

up to 3600 x 1800

Laminated plywood or fibreboard

Hundreds of options:

- Plain colours

- Wood-grain

- Stone effect

- Metals

Finishing

Detailing

Fire Rated Maintaining Lacquer

Contra-Burn® lacquer is offered in a matt finish to provide a natural touch.

This maintains the EN13501-1 fire rated standard that is required in most new projects.

Matt or gloss high strength lacquer provides a tactile finish to enhance and protect the panel.

Standard Lacquer

Acoustic Fleece

Edges

Borders

A black viscose / polyester sheet bonded to the reverse

Fibre-glass free, 180 microns, weighing 50g/m2

Flame retarding class B1

Offered square edged as standard

Loose tongue & groove or chamfered available on request

Factory finishing of edges available if required

50mm borders is the default size

Uniform border widths across different panel sizes create a visually pleasing finish

Solid Panels

Fixing

Battens

Laboratory Measurement of

Random Incidence Sound Absorption to BS EN ISO 354:2003

Tests & Standards

We can supply plain panels to compliment and contrast the acoustic panels.

These panels will be the same production as the perforated panels and undergo the same finishing process to ensure consistency of colour, sheen and texture.

On larger scale projects, we can offer contrasting solid panels to provide a visual break. This could be melamine, veneered or painted finishes.

Screws

Using a stainless steel screw and washer on the border edge of the panels at 300mm centres (24 fixings on outer border). This method makes a feature of the fixing and ideal if panels need removing to access ME services.

Pinning

Using a lost head nail to secure directly into supporting studwork behind at 300mm centres across all areas of the panels. This method provides a clearer face and a permanent fixing method.

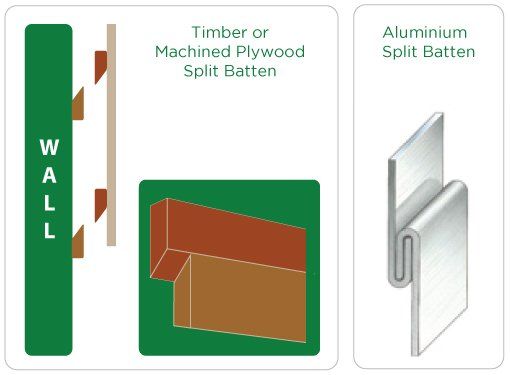

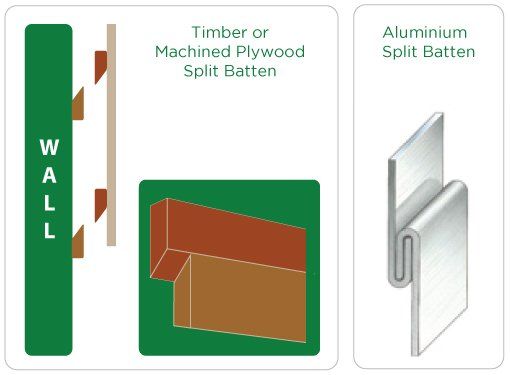

Aluminium Split Battens

A heavy-duty and robust split batten ideal for sports hall or heavy traffic areas where an accessible panel is required.

Timber

40-45mm thick. Standard construction CE marked timbers are generally used working to industry standard timber subframe requirements. This can be supplied as square or to a split batten detail to offer hidden fixing.

Machined Plywood

18mm thick Contra-Burn treated plywood. Best of both worlds: thin and strong, but lightweight and eco-friendly.

Empty Room T1

Empty Room T2

Temperature 17.8 degrees C

Temperature 17.4 degrees C

Humidity 65%RH

Humidity 71%RH

Pressure 1013 mbar

Pressure 1013 mbar

Mounting Method A

Sample Area: 11.91 m2

Chamber Volume: 300m3

Finishing

Detailing

Fire Rated Maintaining Lacquer

Contra-Burn® lacquer is offered in a matt finish to provide a natural touch.

This maintains the EN13501-1 fire rated standard that is required in most new projects.

Matt or gloss high strength lacquer provides a tactile finish to enhance and protect the panel.

Standard Lacquer

Acoustic Fleece

Edges

Borders

A black viscose / polyester sheet bonded to the reverse

Fibre-glass free, 180 microns, weighing 50g/m2

Flame retarding class B1

Offered square edged as standard

Loose tongue & groove or chamfered available on request

Factory finishing of edges available if required

Specify uniform border widths across different panel sizes for a visually pleasing finish

Solid Panels

Fixing

Battens

Laboratory Measurement

of Random Incidence

Sound Absorption to

BS EN ISO 354:2003

Tests & Standards

We can supply plain panels to compliment and contrast the acoustic panels.

These panels will be the same production as the perforated panels and undergo the same finishing process to ensure consistency of colour, sheen and texture.

On larger scale projects, we can offer contrasting solid panels to provide a visual break. This could be melamine, veneered or painted finishes.

Screws

Using a stainless steel screw and washer on the border edge of the panels at 300mm centres (24 fixings on outer border). This method makes a feature of the fixing and ideal if panels need removing to access ME services.

Pinning

Using a lost head nail to secure directly into supporting studwork behind at 300mm centres across all areas of the panels. This method provides a clearer face and a permanent fixing method.

Aluminium Split Battens

A heavy-duty and robust split batten ideal for sports hall or heavy traffic areas where an accessible panel is required.

Timber

40-45mm thick. Standard construction CE marked timbers are generally used working to industry standard timber subframe requirements. This can be supplied as square or to a split batten detail to offer hidden fixing.

Machined Plywood

18mm thick Contra-Burn treated plywood.

Best of both worlds: thin and strong, but lightweight and cost-friendly.

Empty Room

T1

Empty Room

T2

Temperature 17.8 Celsius

Temperature 17.4 Celsius

Humidity

65%RH

Humidity

71%RH

Pressure

1013 mbar

Pressure

1013 mbar

Mounting Method A

Sample Area: 11.91 m2

Chamber Volume:

300m3

0.68

0.95

2500

-

315

2.75

6.44

-

400

6.57

630

1600

0.98

80*

6.06

2.59

1.01

8.00

4.83

-

2000

1.00

3.08

5.56

160

5.40

.

T2

Sec

4.08

63*

7.24

0.78

-

.

T1

Sec

2.37

500

0.17

5.21

3.10

0.67

-

200

7.35

0.60

4.90

2.49

-

0.87

0.61

-

3.14

1.07

0.41

-

-

-

0.85

2.94

0.78

0.90

3.07

-

0.08

1.19

8.04

4.50

0.84

4000

0.46

-

1000

2.65

0.73

3.49

1.46

6.24

n/a

3.29

0.55

1.47

1250

-

4.19

50*

5000

4.22

0.55

250

Test 3

-

7.14

6300*

1.90

2.34

0.80

3.02

0.24

4.06

2.64

.

Freq

Hz

-

2.92

8.41

3150

800

Practical

Absorb

Coeff. #

.

Absorb

Coeff.

1.07

0.58

-

0.61

4.72

6.11

8.10

125

2.25

5.92

0.60

0.68

0.62

100

0.50

1.07

1.86

8000*

10000*

n/a

Test 3

-

.

T2

Sec

4.83

315

2500

2000

50*

-

3.02

2.65

-

0.41

3.14

4.08

3.08

-

8000*

-

0.80

2.25

3.08

-

1.47

3.14

4.19

-

5.21

250

8000*

2000

n/a

125

-

3.29

1600

2.65

-

1.01

4.90

6.06

0.41

0.62

1.86

0.46

6.57

1000

-

1.46

0.60

0.60

.

T1

Sec

-

-

4.19

0.58

63*

400

0.98

2.64

2.37

6.57

10000*

6300*

63*

n/a

1.01

1.19

1000

0.73

0.60

-

-

0.85

2.25

630

1.86

2.49

4000

3.10

-

-

-

0.78

0.67

0.08

0.95

-

4.72

0.55

0.17

4.06

1.07

8.41

-

1.07

n/a

4.22

5000

2.49

0.61

.

Freq

Hz

Test 3

50*

8.10

2.92

0.67

0.24

-

125

630

.

Absorb

Coeff.

-

100

400

1.47

-

6.44

5.21

0.78

1.07

315

1.07

.

Absorb

Coeff.

5.92

4.50

3.49

-

4.90

8.10

Practical

Absorb

Coeff. #

6.24

0.90

7.14

-

0.55

-

100

n/a

6.44

5.56

0.84

0.58

3150

2.94

80*

-

1.07

0.85

7.24

0.98

0.61

.

Freq

Hz

Practical

Absorb

Coeff. #

800

3.10

0.84

1.90

3.02

0.61

4000

2.59

6.11

0.55

3150

4.83

10000*

1600

160

2.75

2.92

0.17

8.41

0.08

8.00

3.07

1.90

5.56

1250

4.50

1.00

800

6.24

-

4.72

1.00

1.07

500

250

2.34

7.14

200

-

0.87

8.04

5.40

6.06

0.46

0.78

0.50

0.24

3.29

5.92

5.40

4.22

1.46

5000

0.95

1.19

-

0.90

-

2.59

160

2.75

3.07

0.62

.

T1

Sec

2.34

200

.

T2

Sec

-

2500

4.06

2.94

0.80

0.50

500

7.24

2.37

8.04

0.60

0.87

80*

0.68

3.49

-

4.08

1250

0.68

0.68

0.55

0.78

0.61

0.68

2.64

6.11

6300*

7.35

7.35

8.00

0.73

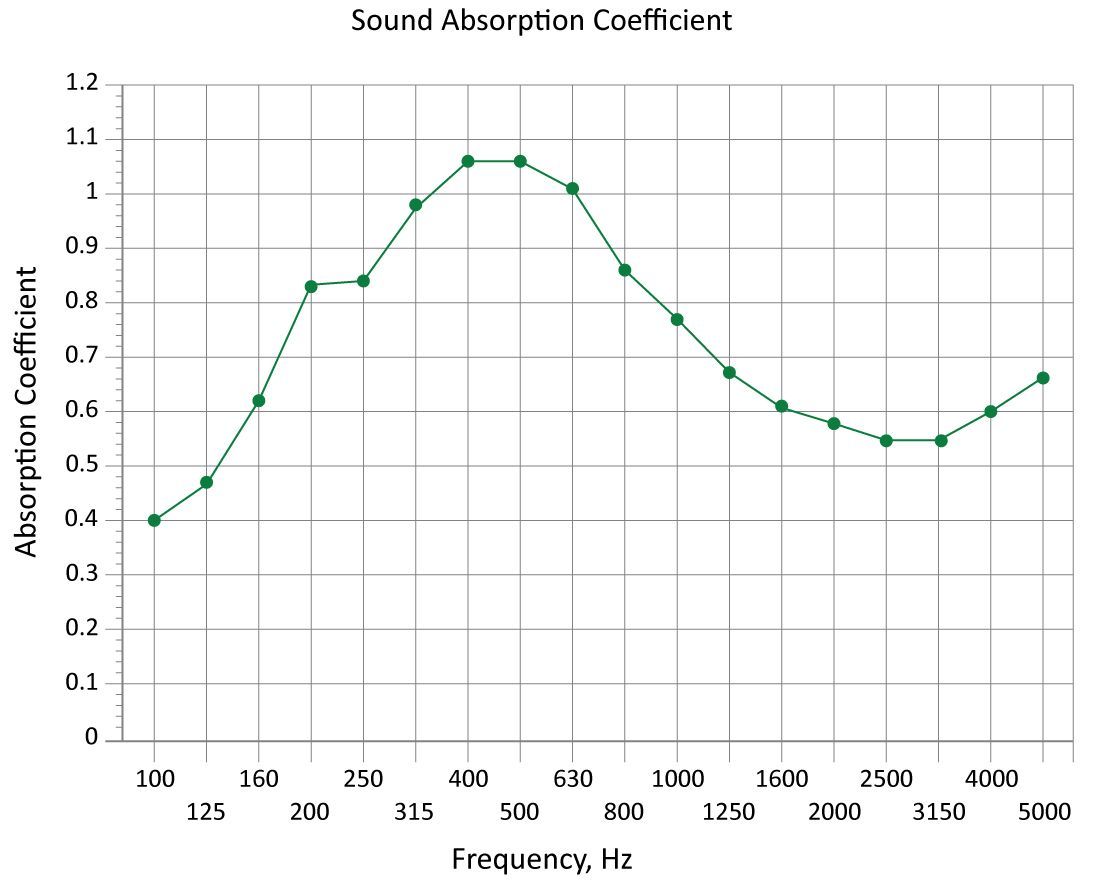

Sound Absorption

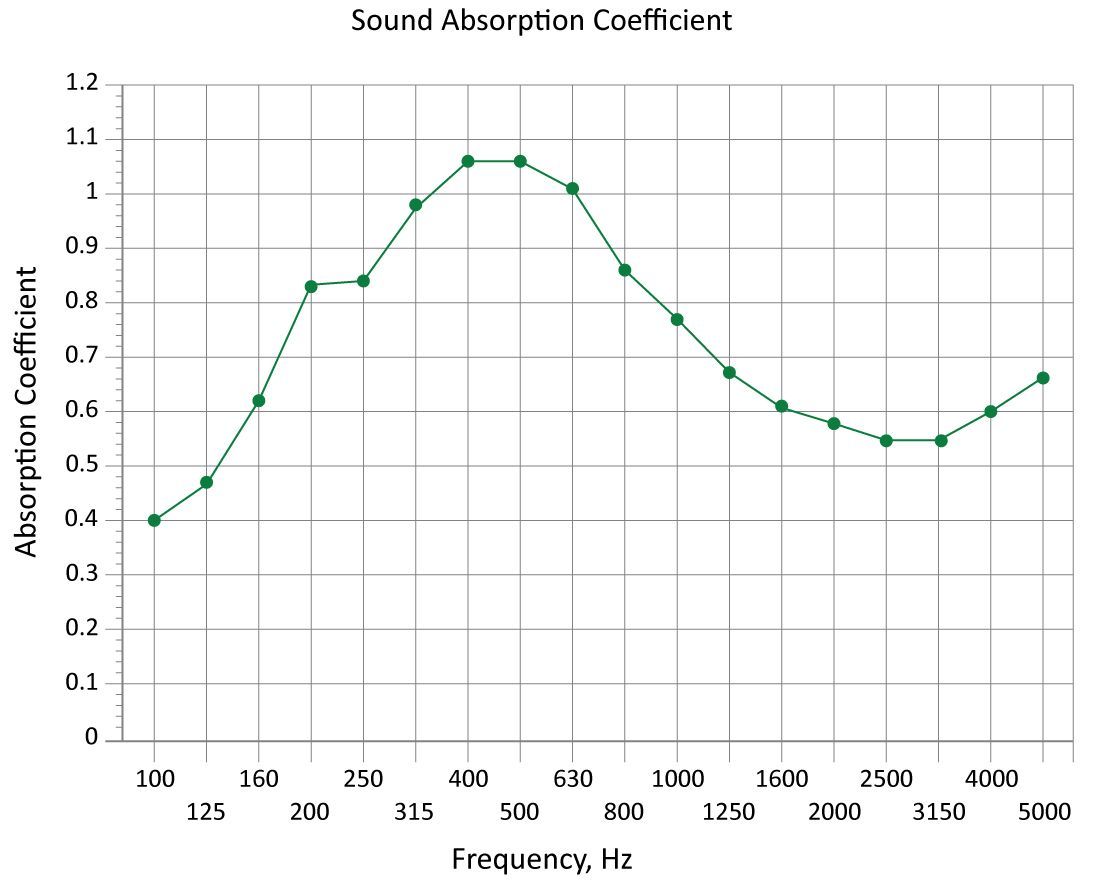

Independently tested standard perforations to meet BS 8233:2014. We work with clients, architects and designers to achieve the acoustic rating and visual aesthetics required for the project.

Acoustic absorption is achieved by sound waves passing through the open area in our panels and baffled by the acoustic fleece behind. Our standard range of machining patterns achieves a high Class C rating (with potential for a higher rating using bespoke machining or additional insulation behind the panels)

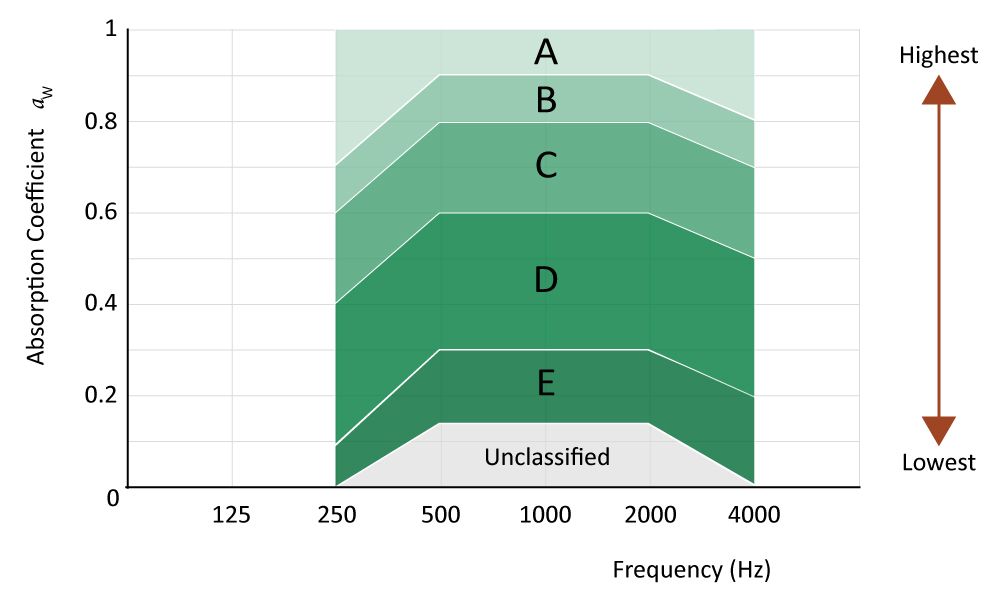

ISO 11654:1997 Acoustics – Sound absorbers for use in buildings – Rating of sound absorption

Testing terminology - BS EN ISO 354:2003 Acoustics. Measurement of sound absorption in a reverberation room

The material’s ability to absorb sound is generally presented with absorption coefficients measured in different frequencies. This means in practice that one material has a number of different absorption coefficients based on frequencies.

When specifying a suitable absorption class for each product, a product is first measured according to EN ISO 354:2003. The result from this test is an absorption curve, which declares absorption coefficients for each frequency used in the test.

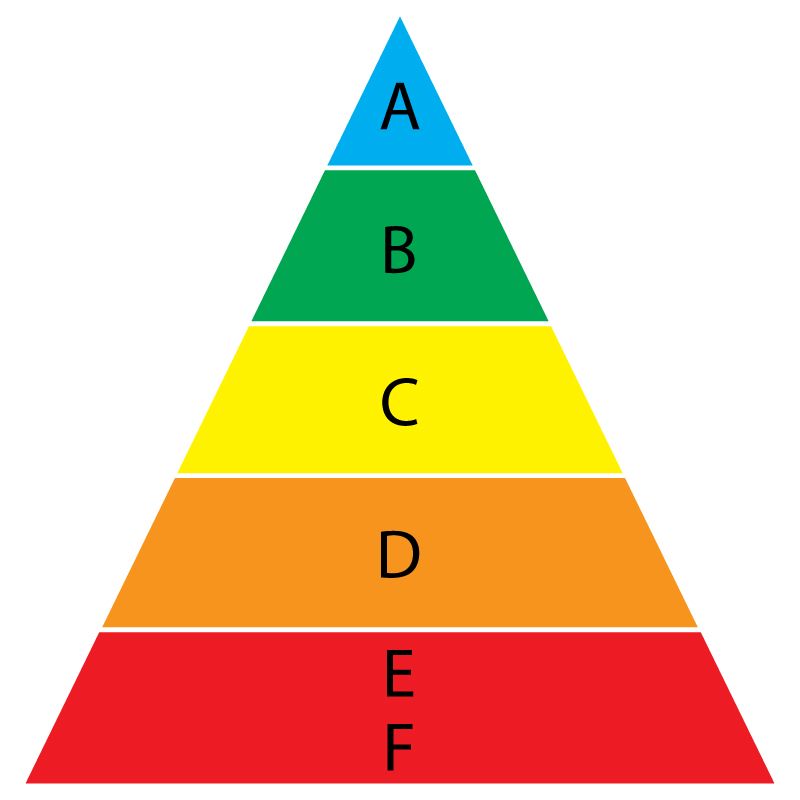

Fire Retardancy

When looking at a project the risk of fire is a key focus point for any design. With the harmonized standards of BS EN 13501 construction products are classified dependent upon their risk, with A being non combustible and F being flammable.

Within every build there is a requirement to meet a minimum standard with a requirement of Euro Class B in most non residential projects such as sports halls and education facilities. This is also combined with a minimum standard for smoke graded from 0-3 and flaming droplets graded from 0-3.

Due to our experience within the fire retardancy market we can offer over 90% of our panel options to Euro B-s2,d0 where fire protection is required. Our system is independently tested and we can offer compatible finishing coatings to offer a product that will last the test of time.

The standard will be displayed as Euro B-s1,d0

Fire Classification Details

Panels

Every panel we supply is subject to a wide range of testing requirements including:

Environmental Rating

All boards comply to both EUTR and UKTR requirements and where required can be offered as FSC or PEFC certified.

Board Structure

This includes a declaration of performance from the producing mill and contains key information such as glue type, board strength, board density and use class.

Face Grades

We offer our panels with defined face grades, these meet set standards in terms of appearance and have guidelines on allowable natural defects such as knots, fillers and colour variation.

Additional Services

For over 25 years we have supplied acoustic sheet material to the market. We know that service and experience is just as important as the high quality product supplied for your project.

Please speak to our team for further information on:

Project Discussions

Arrange an online video call with our team to discuss your project in detail - including budgets, timescale and specification.

Project Specification

Discuss your requirements in detail with our team who can advise on options and provide feedback on NBS specification.

Take-Off

Our team can review details with you to provide support when reviewing requirements.

Technical

Draw on our broad knowledge of panel products & timber. Our team can discuss technical aspects of your project including fixing and finishing details.

Specialist Packing

Part labelling - numbered as per your elevations for easy installation.

Sequential packing / elevation separation - packed in order of installation sequence to help with project scheduling.

Bespoke Supply Service

FORS, CLOCS, multi-drop JIT deliveries - our team can meet your site delivery requirements.

αw

1.00-0.95-0.90

0.85-0.80

0.75-0.70-0.65-0.60

0.55-0.50-0.45-0.35-0.30

0.25-0.20-0.15

0.10-0.05-0.00

Zero represents no absorption

Sound Absorption Class

A

B

C

D

E

Not Classified

A1

A2-s1,d0

B-s1,d0

B-s2,d0

B-s3,d0

C-s1,d0

C-s2,d0

C-s3,d0

D-s1,d0

D-s2,d0

D-s3,d0

E-d2

F

Non Combustible

Mineral based products or those with very low organic content

Low Combustibility

Organic products with high levels of additives to resist fire

Difficult Combustion

Fire retardant organic materials

Medium Combustion

Organic products protect from flame or self-extinguishing

Flammable or unclassified

Euro

B

Combustibility

Smoke

Droplets

s1

d0

-

4.72

5.21

4.08

0.17

n/a

4.90

6.11

7.24

8.04

7.35

8.00

8.41

8.10

7.14

6.24

4.50

4.19

4.22

3.49

3.02

3.07

2.75

2.49

2.37

0.24

0.41

0.46

0.62

0.84

0.85

0.98

1.07

1.07

-

-

1.00

-

-

0.50

-

-

0.90

50*

63*

80*

100

125

160

200

1000

1250

1600

8000*

1.47

1.90

2.59

3.29

4.06

4.83

5.40

5.92

6.44

6.57

6.06

5.56

1.19

1.46

1.86

2.25

2.65

2.94

3.08

3.14

3.10

2.92

2.64

2.34

0.78

0.73

0.67

0.61

0.55

0.55

0.58

0.61

0.68

0.78

0.87

1.01

n/a

-

-

0.60

-

-

0.60

-

-

0.80

-

-

10000*

1.07

0.95

0.68

-

4000

5000

2000

2500

6300*

3150

250

315

400

500

630

800

0.08

.

Freq

Hz

.

T1

Sec

.

T2

Sec

.

Absorb

Coeff.

Practical

Absorb

Coeff. #

Test 3

αw 0.70 (LM)

Class C to EN ISO 11654:1997

NCR 0.80

calculated to ASTMC 423-01

* denotes frequencies outside the range

covered by BS EN ISO 354:2003

T1 - empty room reverberation time

T2 - room reverberation time with sample

# Practical absorption coefficient

BS EN ISO 11654:1997